The Cape Town, South Africa-based ink manufacturer chooses renewable energy for production.

The company actively engages in waste elimination and sustainable production.

David Dupee, a lawyer by training and social entrepreneur, co-founded Good City Brewing in Milwaukee.

Ryan Strowger comes to ISA with experience in events management.

She entwines her community contributions with sign technology.

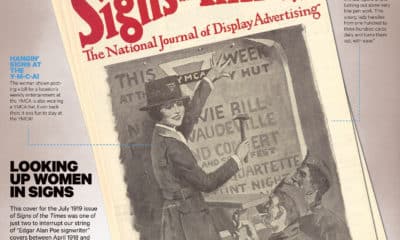

Plus, an editorial shoutout to a talented woman showcard writer.

The executive director has worked with several ISA-affiliated organizations and committees.

Her industry approach emphasizes education and emotional intelligence.

The two are looking into areas to optimize procurement, production efficiencies and more.

Anthony De Francesco, Alex Folloso and Kim Hill led their teams to improve innovation and productivity.

The digital sign printing package comes with Avery Dennison inks and media.