LEDs + Lighting

The One-Man Band

Typical pitfalls in a small, neon business

Published

18 years agoon

Roughly 75% of U.S. neon shops (or neon departments in larger signshops) are run as small business units with one or two workers. Obviously, neon signmaking requires special training and equipment. Thus, many neonbenders start their own signshops.

Because a complete neon sign entails many different fields, such as glasswork, metal and electrical work, a single person can’t do everything. So, specialization is the keyword for most neon shops. Before finding your niche in the wide area of neon signmaking, know that your success running a small business will depend on two key factors: a sufficient quantity of customers who trust you, and enough helpers and suppliers you can trust.

If you plan to run a full-service neon signshop, helpers play an important role — even hanging a small window sign requires more than two hands. Owners of such shops often spend most of their time delegating jobs, because they can’t make a living doing all the tasks themselves.

Ideally, a one- or two-person shop would exclusively handle wholesale glasswork. Thus, I’ll focus my advice toward this setup.

Get a good start

Besides gathering information about business opportunities, you need financial backbone to get started. But, don’t rely on banks. Instead, investigate other financial sources. Governmental (such as the Small Business Administration) or local authorities often assist potential business owners. Some even provide non-refundable monetary support.

Many business failures start with a big bang. Eager owners often acquire fancy office furniture, the most advanced computing equipment, a cover model at the front desk and a big, company car. Already, they’ve slimmed down their wallet. And they often build a business on credit, thereby giving their money to the bank.

Instead, start small. Invest all earnings into the business (which makes it tax deductible). Before starting, provide enough money to make a living for at least the first six months. Then, most businesses run on their own, and perhaps they’ll make a profit in five years.

To reduce initial costs, I (and many other business owners I know) bought used equipment. Used” doesn’t mean worn or in bad shape. Newspapers and trade magazines often advertise company close-outs or used- or surplus-equipment sales.

Emphasize quality

The various tasks in fabricating a neon sign almost preclude running a successful, one-person shop. A good glassbender isn’t necessarily a good sheetmetal worker or electrician. You’ll never achieve an outstanding reputation or market position (except in the middle of nowhere) if everything you produce reflects average workmanship. Also, your business is doomed if you’re not satisfied by your work. For every project, you must convince yourself and others that your work reflects quality craftsmanship. Only your sincere belief in your product (an Oscar-winning performance won’t suffice) conveys this conviction to your customers.

Sign companies choose to work with neon shops that quickly turn around work, meet deadlines and produce quality work. Sloppy bends simply don’t make a good impression!

Sell yourself

Even if you’re not your shop’s official salesperson, your most important task as a small-shop owner is to sell. Potential clients probably won’t call if you don’t call them first.

To sell your shop’s services, you must actively present them to the public and be available at any time for possible client calls. Be prepared to be frequently interrupted while working. These interruptions disturb my workflow, but I realize that clients consider their jobs to be the most important and most urgent calls I receive.

To cope with the calls, define what inquiries are so urgent that you’ll interrupt your work. In most cases, each day I take careful notes and put them on the “to do” list. Serious quotes take first priority.

Make sure you can easily access a phone in your various work areas, and set the ringtone volume on “loud” (or even add an additional siren/flashlight!), so you won’t miss calls because you’re in a noisy environment.

Most importantly, you must be self-disciplined. Every morning, get to the shop on time, even if no project awaits you, or even if you’re just not in the mood to work. As a popular comic says, “Get ‘er done.”

In order to dedicate all your time to sales and your neon work, don’t waste time fixing your own, broken equipment. A successful neon business mandates reliable machinery — especially the pumping system, vacuum gauge and the air blower for the fires.

Bombarders rarely go bad. Used equipment has its pitfalls. Because product quality hinges on the vacuum system’s performance, I strongly recommend that you ask the manufacturer’s shop to overhaul and calibrate it. That’s still less expensive than buying new equipment.

For example, at first, you don’t need a large-format printer to make patterns. Using calipers and a calculator, I enlarged patterns in the photocopy shop next door, then taped the sheets together. Many lighting designers and sign companies e-mail drawings, which are often “AutoCAD” formats. Don’t forget to calibrate your printouts so they’ll be accurate. Also, consider outsourcing plotter work.

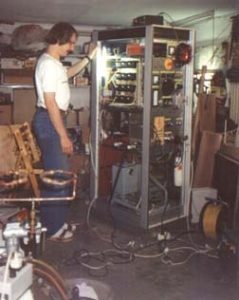

Running a small neon shop from your own property (a.k.a. garage) saves money (you can commute between work and home in seconds). But, later, clients will judge your products as “backyard homebrew.” Additionally, a streetfront shop window can draw many customers. Always keep an eye on your overhead, but never sacrifice professionalism.

Plan ahead

Shop layout requires not only organizing and optimizing various tasks, but also realizing possible limits (see ST, October 1999, page 60).

Always consider future expansion. A neon shop requires ample electrical power, and 200A, three-phase service suffices, but will that fit future needs?

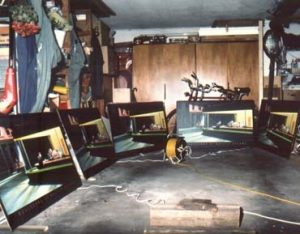

Workshop room height can set limits. How do you handle an 8-ft. border tube in a 7-ft.-high garage or basement? If your throughput is small, tables can serve multiple tasks, but always provide ample space to place parts and tools needed throughout the project. Use the bombarding table for aging only if you’re not bombarding another unit while the one you’ve just made is aging.

Clear “stuff” from the bending table, too. Often, when I was starting out, and tried to place hot glass onto the pattern, the straight tube end would poke into tools “put there for a moment,” which ruined the bend. Torches and the pumping system can be placed on wheels, so they can be moved out of reach when not needed. Storing glass underneath the bending table also saves space. Presenting the patterns with the glass to the client saves storage space and also frees you from retrieving them.

Working with wood and plastic creates dust, which can’t be tolerated in the glass shop. Also avoid paint fumes and wandering spraypaint clouds. Thus, if you want to provide a full-service company, you must separate your workspaces to avoid contaminating your glass.

If you’re bending and pumping yourself, you can’t do both simultaneously. Focusing on a task takes time and patience. You can’t produce perfect bends or allow an adequate pump by always switching between the two tasks. Most people either bend in the morning and pump in the afternoon, or complete all the bends for one job, then pump it the next day.

When taking a new job, I first check material availability, and, if they’re not available, when they’re available. Some hard-to-get colors, especially for repairs, are out of the question. A small shop can’t keep a huge stock of different glass colors and diameters. Some suppliers overnight a few sticks of glass. You can also coat clear glass using a no-bake or dry-coating process.

Only after I know if all materials have been, or can be, secured do I give the client an estimated timeframe. It’s always better to overestimate time and price, then surprise the client that you could pull off a miracle at an early date and actually charge a little less than estimated. “Lucky” clients always return.

Running my own business for the last seven years has given me personal freedom and the direct satisfaction of seeing my own work become a reality. Sometimes, I force myself into the 12- to 14-hour day, but even this little bit of self-discipline is worth being my own boss.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet4 days ago

Tip Sheet4 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks24 hours ago

Benchmarks24 hours ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines