Design

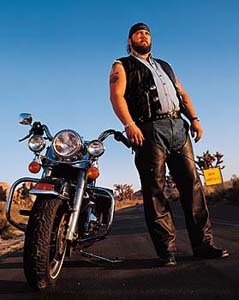

The Men Behind the Hog

Insight from the Harley-Davidson stylists

Published

18 years agoon

In this sign-industry exclusive, Harley-Davidson’s stylists share insight into their company’s product development, graphic design and fabrication

Think it’s difficult creating graphics that will please one customer? Try creating graphics that will please thousands. At Harley-Davidson Motor Co. (H-D), Milwaukee, Wis., that next-to-impossible task is charged to the Styling Dept. staff, including Vice President Willie G. Davidson, Dept. Director Louie Netz and Graphic Designer Ray Drea.

We interviewed Netz and Drea and found out how they design new products and modify the graphics on existing bikes. We also learned how Harley graphics are fabricated, and discovered that Drea’s background is in — what else? — sign-making.

Briefly describe Harley’s overall product-development process.

Netz: The process is initiated through a 10-person product committee that includes the heads of various departments –Marketing, Manufacturing, Engineering, etc. It’s this committee that determines H-D Motor Co.’s product-development plan.

Product development may involve the creation of simple derivative models, where we’re creating a spin-off of an existing platform. In other words, it may involve situations where we’re using an existing engine and chassis, but incorporating different sheet metal, saddle bags, handlebars, instrumentation, etc. Our Softtail model, for example, is a platform. It has a chassis that falls into our custom family of motorcycles, but it also has six or seven derivative models, each of which has unique styling elements. Some of these derivatives are true nostalgia-type bikes, some fall into our extreme custom line, and others fall somewhere in between. Derivative models take us two or three years, at most, to develop.

In addition to derivatives, product development may involve plans that encompass large changes, like new engines. These products obviously take us considerably longer to create. There’s more workload and R&D involved, especially for our Engineering and Manufacturing departments.

All of our product plans extend five years and longer. The plans are vague after five years, and flexible when the products are between two and five years out. But they become quite fixed and rigid when we’re only two years away from production and distribution. For instance, at this point, we would upset the Harley organization if we made dramatic changes to our product plan for the year 2000. We need to keep a cadence for what we’re working toward.

What is the Styling Dept.’s specific role in product development?

Netz: We are intimately involved in the development of new products, whether it’s the styling of a chassis, a derivative model or power trains. We are responsible for anything that affects what these motorcycles look like, and that can include the obvious things, like paint and trim, the geometry of fenders and seats, or engine covers. We don’t design the CAM gears or the valve train, but we design the covers for those components by working closely with engineers.

Graphic design is actually separate from the product-development process itself because graphics on a given project change regularly. Generally speaking, we try to update a graphic every 3-5 years. There are some graphics, however, we don’t alter, because they really identify a specific model — Fat Boy graphics, for example. We try to maintain the Fat Boy graphic because it’s what really gives that bike its look.

Does a motorcycle’s look develop in tandem with its engineering? Or do you handle styling after the fact,” so to speak?

Netz: It works both ways. The Styling Dept. has a product all along. In other words, we are styling a product right now that’s five years out. And we’ll work on its styling right up until the day it’s released. And then we’ll continue to work on it on an annual basis from a graphics standpoint, upgrading features, making model-year changes, etc. So we are with a product from its very birth until it’s no longer offered on the marketplace.

H-D offers a highly emotional product, with a strong image and a very loyal customer following. We need to be sensitive to these issues, yet we also need to upgrade and improve our product. We’re no different than other organizations. There are ongoing, classic confrontations among Styling, Manufacturing, Engineering, Marketing. Product development is a give-and-take process.

There’s a statement coined by Willie G. that I think accurately describes the development process. He says: We believe that form needs to follow function, because first and foremost, motorcycles truly need to work. But both form and function report to emotion, and if these products don’t do something to you in a very emotional way, we won’t capture you in the first place.

How large is Harley’s Styling Department?

Netz: We’re a small department, by choice. Willie G., as mentioned, is the Vice President of Styling, I’m the Dept. Director, Ray Drea is our Graphic Designer, and we have two other designers as well. So there is a total staff of five, plus an administrative assistant, who works exclusively for our department. We also have a full-time model-maker from the engineering lab who is assigned to us.

What types of design equipment do you employ?

Netz: We incorporate traditional design methods, as well as CAID — computer-aided industrial design. The software we use is high-end — ProDesigner, by Parametric Technologies. We’ve found that ProDesigner works well with ProEngineer, which is our company’s base engineering CAD system; our styling data transfers easily to it and vice versa.

Color and Trim Choice

You mentioned the full-time model-maker who works with you. Please describe his role in the Styling Department

Netz: When we design using traditional methods — renderings, illustrations, etc. — he makes these designs into full-size mock-ups, using foam, clay, body filler, basically any material that suits his purpose.

Actually, even if we’re designing via electronic processes, we still verify our work through full-size mock-ups. We use a variety of rapid prototyping techniques, including stereolithography, CNC machining and LOM.

Regarding graphics, I would assume that paint choice is among the most significant decisions you make. When and how do you determine what paint is used?

Drea: It’s usually when the product is further along in its development process — about one year before the bike will be released. As a department, we’ll see what paint we have available to us at the time, or determine whether we need to develop a new color for a specific bike.

We have a paint and trim chart that basically defines the colors that will be available in a given year, what models the colors will be on, what colors the bikes will be striped, what decals will be used and their part numbers. In Styling, we are solely responsible for creating and maintaining the color chart; Marketing, Engineering and other departments have no role in color selection.

Actually, I’m surprised the Marketing Department doesn’t play a greater role in deciding color; I would think color is a key marketing issue when selling the bikes.

Drea: Our department doesn’t lock itself in a closet. We’re out with the customer all the time at motorcycle rallies and other engagements. So we have a good sense of what our customers like.

Netz: I want to add that in the recent past, our company has been very fortunate. We’ve been getting very positive feedback from our customers in terms of both color selection and graphics. So I think the Marketing Department. is very happy with us. They leave us alone because things are going well.

How do you choose a color scheme for a particular bike model?

Drea: That has more has to do with what colors are available or what colors we are working with at a given time, unless it’s a specific bike on which we think there’s only one color that will work.

Netz: For any given model, we typically offer four or five colors, sometimes six. Usually, there are three or four solid-color offerings, and two or three two-tone-color offerings. Across the board, regardless of bike style, our volume is a steady 40-percent black. And then we need to offer a very good red, and a very good blue. These are the mainstays of our color selection.

Only 10 percent of our sales are for fringe-color bikes. Purples and oranges are way down the list percentage-wise, but the colors are used on our extreme custom bikes. And yet the same bright colors wouldn’t lend themselves to touring bikes, where we try to use more elegant combinations — green with black, blue with silver.

Drea: A lot of fringe colors, I might add, come from looking at the automotive market. You can see right now that green is a very popular color. Non-metallic turquoise with off-white, and peach with cream are popular for our nostalgia models; they’re colors you would have seen on ’50s automobiles.

What brand of paint do you use? How and where is it applied?

Netz: On all our products, we use PPG-brand, acrylic, solvent-based paint with a powder clearcoat over it. Our paint system is located at our York, Penn., plant, which is where our chassis fabrication and final assembly takes place.

In fact, we recently opened a new state-of-the-art paint facility in York that’s coming on-line soon. The facility represents a huge investment and offers an electrostatic-coat priming system, followed by a high-solids, baking acrylic enamel, and then a powder acrylic-based clearcoat.

To my knowledge, we are leading the world in the class of paint finish we produce. It’s been reported that our fuel tanks — based on their distinctness of image, gloss, etc. — easily qualify as triple-A automotive finish. That quality is part of what we sell.

After color selection, what’s the next step in the graphics-design process?

Drea: The next step is graphics — the bike decals themselves. At this step, I draw up a half-dozen or dozen ideas, and then I throw them back and forth between Louie, Willie G. and myself.

I create typestyles for our graphics, rather than using something from computer that’s readily available and anybody can copy. Often, I use a brush and paint the original lettering and graphic, just like a sign painter would, because I have a lot of experience doing so. I may also use a pentagraph pen on illustration board. Occasionally, I’ll use a computer if I need to pull up a specific type, like Americana, and place it on an arc or an oval. But when I’m creating something simple, say, the name “Harley-Davidson” combined with a few other graphic features, I’m faster working by hand.

Once I’ve created a design, incidentally, I create camera-ready art, which we forward on to the graphics supplier.

Riding to the Top

So, your background is in sign painting? How did you become involved with H-D?

Drea: I’ve done sign painting for about 20 years, as well as custom painting, pinstriping, mural work, you name it. I’ve been Harley’s Graphic Designer for five years, but I’ve actually done work for the company since 1980, as a consultant or an outside source.

Netz: We consider Ray’s sign-painting background a huge benefit. Ray is responsible for all of the graphics that we do. It’s a tremendous plus that all of our fuel-tank typography — which we consider sacred — is one-of-a-kind and hand-created. It isn’t typography that someone else has on their computer. The lettering has a feel and a look that matches perfectly with H-D corporately, and yet it’s also model-specific.

After all, the number-one centerpiece of our motorcycle is our engine. It’s a cycle’s visual center, and also its heart. But the number two most important part of a motorcycle, from a styling standpoint, is the fuel tank. And probably the most important thing we put on that fuel tank is the “Harley-Davidson” name. Sometimes we’ll also include a product’s model name — on a Sportster, for example — but that’s very rare.

How are Drea’s graphics fabricated?

Netz: Sometimes we use vinyl decals on our fuel tanks. Sometimes we screen print directly onto the fuel tanks because we want fine detail we can’t achieve via a vinyl transfer. Also, at times we incorporate cloisonné and chrome nameplates onto our fuel tanks. And sometimes, we use a combination of these three methods.

Various factors determine what type of graphic we use on a particular product: cost, and the need to meet certain price points; the look we’re trying to achieve, be it a classic style or a more expensive-looking bike; and how we hope to differentiate the product within its model line. (Editor’s note: Cloisonneé is enamelware in which the surface decoration is formed by different colors of enamel separated by thin strips of metal set on edge.)

Is the vinyl-decal fabrication, the screen printing and/or the cloisonné nameplate fabrication done in-house?

Netz: The vinyl decals are outsourced to a local screen printer, Color Arts, in Racine, Wis. They generally print the images onto 3M material. When it comes to screen printing directly onto motorcycles, though, we do that within our factory.

Cloisonné nameplates are made with a bronze-like material that is coined and then inlaid with glass. The piece is then fired, ground smooth, polished and chrome-plated. But the chrome only sticks where the metal is showing; it doesn’t stick on the glass. Because cloisonné is an old-world process, and we need to have these parts made so they’ll fit on the curvature of our tank. There’s a large scrap factor in their manufacture. The nameplates are applied to tanks with 3M automotive adhesive.

Where are the vinyl decals and nameplates installed?

Netz: Like the screen printing, they’re done at the York plant. The decal-application operation is pretty interesting. There’s a lot that goes on to ensure that the graphic elements are properly positioned. Alignment is very important. You can have a great graphic design, but if it’s put in the wrong place on the tank, then you’ve lost the context.

We’re using some pretty sophisticated methods for keeping alignment: We have lasers that project an image onto a fuel tank held in a fixture. These laser lines are then registered with registration marks on the decal, so that the decals are located perfectly each time.

Is the pinstriping process similarly automated?

Netz: No, pinstriping is applied by a wheel, versus decals. Our bikes are hand-striped to this date, usually using acrylic automotive paints.

Are there any other graphics you design for a motorcycle?

Netz: Well, like I said, we might apply graphics to the air cleaner or the timer cover. Sometimes, we’ll also design embroidered or heat-sealed graphics for the seat. We may also put embroidery on the saddle bag, or on the back of the sissy bar. Basically, we coordinate all the graphics so that they make sense.

Where the embroidery is fabricated for a particular bike depends on who is making that bike’s seat. Our main OE seat manufacturer is Milsco Mfg., located in Milwaukee.

H-D celebrates its 95th anniversary this year — congratulations, by the way! Could you describe the graphics on your anniversary line of bikes, and how they were created?

Netz: Well, for those models, Willie G. actually came up with the design. We created the camera-ready art from his designs and had them rendered as cloisonné nameplates. Willie G. often pens logos for special H-D events.

Harley has more accessories available than any other vehicle. Do you help design those accessories?

Netz: When we have the time to do so, we help with different products — the way a seat is going to look, for instance. In terms of non-bike products — jackets and shirts, etc. — when that department was smaller, we used to help out with the graphics. Now, about the only thing that happens is that a year after we design a new graphic for a gas tank, the department will incorporate the graphic onto some of their products.

Many of your customers hire Signs of the Times readers to create custom paint jobs on their Harleys. Any thoughts on this practice?

Drea: We don’t mind it at all. They’re enjoying the product. That’s part of the sport: People want to personalize their bikes. And they start out with all the simple accessories that H-D offers. And as they progress in their enjoyment of their bikes as a hobby, they may get into custom paint.

One footnote though: Even with our creative abilities, Willie, Louie and I still prefer to see bikes stock. Our ideal bikes are totally stock, without any custom detailing on them.

Is there any subject we haven’t touched on in terms of Harley’s graphics design? Or anything you want to make clear to our readers?

Netz: Nothing other than: Get on a motorcycle and ride!

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Orbus Celebrates Earth Day With Recycling Achievements

American Sign Museum Names New Executive Director

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery2 days ago

Photo Gallery2 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks7 days ago

Benchmarks7 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Ashley Borell