Electric Signs

Pop the Cork

A Denver liquor store enjoys mile-high stature thanks to its building signage.

Published

15 years agoon

Buchanan Yonushewski Group LLC (BYG), a well-respected, Denver-based architectural and construction firm, contacted Rick Bellefeuille, an account executive at Young Electric Sign Co.’s (YESCO) Denver office, to create an innovative sign design for Argonaut Wine & Liquor’s new store. Argonaut’s new building comprises part of a revitalization effort within Denver’s Capitol Hill neighborhood.

Hampton Development, the developer of the new Argonaut store, BYG and YESCO collaborated toward a straightforward goal: devising a unique sign that would provide an unforgettable landmark and entice customers through the door while not appearing garish.

The drawing board

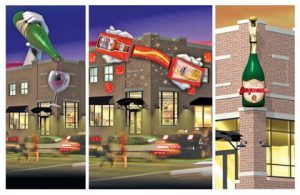

Fortunately, I became involved early in the brainstorming process. I created concept renderings derived from several client meetings. We concocted some wild initial concepts – we considered a giant, Mickey Mouse-like hand holding a wine glass while a bottle held in the other poured liquid. After further discussion, we decided thousands of gallons of fluid flowing overhead might prove problematic.

Our next mechanically feasible idea involved building an enormous forearm that held an outsized wine bottle teetering over the building’s edge. This idea tantalized me during our design meetings, but, as my Lightwave3D® software rendered the concept on my screen, I decided our concept would yield a funny, but creepy, sign.

AdvertisementRick and I knew our customer wanted to see this latest idea on paper, and I predicted this idea would float like a lead balloon at the next design meeting. After a few laughs, we started asking some deeper questions about how the sign should function for the store.

Even though our preliminary ideas would’ve provided curb appeal, they failed to affirm Argonaut’s brand identity. After some deliberation, we realized our design should incorporate electronic message centers (EMCs). With a new emphasis on EMCs, we revisited the “Mickey” concept, but dumped the idea of thousands of gallons of fluid in favor of thousands of points of LED light.

This seemed promising, but our original scale exceeded electric-sign square footage allowed by Denver’s sign codes. We thought adapting the concept to meet code would drastically diminish this design’s visual impact, so it sank down the drain.

Go with the flow

AdvertisementAfter the demise of the revamped “Mickey” design, I sharpened my pencil and returned to the drawing board. Ron Vaughn, the store’s co-owner, mentioned that, in the ‘60s, the former Argonaut store featured a bottle-shaped sign cabinet with skeleton neon cantilevered off the building’s corner. Ron’s comment had jogged my memory, and I recalled YESCO’s production of a large, fiberglass ketchup bottle for Heinz Field (see ST, June 2003, page 88).

Armed with this newfound inspiration, I reopened Lightwave3D and modeled a few more virtual concepts. Confident one of the new concepts would persuade our customer, I generated several 3-D models of various sizes, colors and bottle shapes with various attached signage options.

Using these virtual models of the sign, and an animation that drove our customers down a virtual street, YESCO provided a real-world view to the client their potential sign. With the help of the 3-D presentation, we triaged some details and nailed down the final, magnum-sized design.

Next, we navigated the permitting process. This proved arduous because Denver’s code had no real precedent for this sign type. The code did provide for “unique” signs; this formula measured total volume instead of square footage. This volume-measurement method confused us initially due to the bottle’s complex shape. City planners put a cubed rectangle around the bottle, and their measurement far exceeded the limit.

Luckily, the modeling software enabled us to measure the bottle’s true volume, which adjusted the sign to near Denver’s allowed maximum. With a few program modifications, we reached our target, and the city gave us the green light.

AdvertisementBottled up

Lightwave3D’s models proved useful for fabrication as well as presentation. They allowed us to view the bottle from multiple angles, which enabled our sculptors to craft them using expanded-polystyrene (EPS) foam with very little guesswork. The files also helped BYG engineers place steel reinforcements on the building to support the sign.

The 3-D process also simplified the bottle’s label and letter layout. With it, I virtually wrapped the label on the bottle’s curved form, which the software flattened into a template that Mike Benzie, our art-production supervisor, used to produce the digital-print template. Fairpoint Graphics (Denver) produced the digital graphics on 3M’s Controltac film with a Fujifilm’s Acuity Advance UV-ink printer. Because we could deconstruct the sign’s many components in virtual space, we generated an accurate layout for the channel-letter standoffs and electrical-feed locations.

Artisans in YESCO’s Las Vegas-based sculpture department started the fabrication process by creating an EPS form, which they used to create a bottle mold. The mold worked similarly to a cake pan in shaping the appearance. However, instead of cake batter, we “layup” fiberglass.

Layup involves the application of a resin-coated, bi-directional fiberglass mat that’s built up, layer by layer, inside the bottle mold. When the resin completely cures, we pull the fiberglass shell from its mold. The sculptors also fabricated the bottle topper, which comprises a gold-foil collar, splashing foam and a popping cork.

Before shipping the shell and topper to our Denver division, our Las Vegas steelworkers built the necessary steel structure, fitted inside the bottle, and matchplates to mate the topper to the bottle. We transported the unfinished bottle from Las Vegas to our Denver facility for the finishing touches.

Our lead painter, Lawrence Muder, applied a beautiful, metallic-green, three-stage Dupont Imron® finish. He added several clearcoat layers to provide a deep, wet-look finish. With the paintwork complete, it was off to our electrical and plastics department.

Next, we added the vinyl label, channel letters and the topper. First, Tom Torbeck, our plastics-department manager, applied the bottle’s champagne label. Then, Tom and Mike Dack, our electrical manager, mounted the SloanLED-lit channel letters (the 3-D rendering helped us set the standoffs). Finally, they installed and wired the fiberoptic-filled topper.

A moving message

While our Las Vegas and Denver plants assembled the bottle, our Logan, UT-based, electronics division assembled the program’s electronic message centers (EMCs). Our customer wanted to deliver high-resolution content, so we recommended 12- and 20mm, full-color EMCs that display more than 16 million colors of full-motion video. YESCO’s Prismview graphic software drives the application; we installed it on Argonaut’s server for convenient access and simple updating.

When all the finished components converged at our Denver plant, we were ready for installation. To contend with tight deadlines and harsh Colorado weather, we enlisted Mike Roybal and Chad Mikalson’s installation team; Bill Ferguson and Mick Bodah, our respective installation and project managers, supervised the project.

Chad climbed through a relatively small hole to access the bottle and make final connections. His emergence from Argonaut’s newly attached bottle made the front page of the Denver Post’s business section. The three-day installation differed little from most jobs, but the media circus that accompanied the install was surely unique. With one final hand polish from our installers, we completed the project.

To pop a cork this large requires a major effort from many people. You need customers and developers with vision, artisans with exceptional skills, two years of diligence and a little voltage to electrify a crowd waiting to see a venerable establishment make a giant splash.

On a frosty December morning in Denver, Argonaut Wine & Liquor re-opened in grandiose fashion. An iconic sign for an equally iconic liquor store came to life. A

project two years in the making was electrified before an enthusiastic crowd of loyal customers and community leaders that included John Hickenlooper, Denver’s mayor. Our innovative sign proclaimed the reopening of the 44-year-old store within this two-story, brick building.

About Herm Medina

Herm Medina, who has more than 15 years of design experience, works as art director for YESCO’s Denver division. He started his career developing casino slot-topper displays in Las Vegas. In the mid-‘90s, Herm transitioned from hand-drafted designs to digital design and expanded his repertoire. In 2001, he transferred to YESCO’s Denver office, where he now lives with his wife and two-year-old son.

Equipment and Materials

Coatings: Imron® polyurethane enamel, from DuPont (Wilmington, DE), (302) 772-8000 or pc.dupont.com; pearlescent; Pearl concentrate, from House of Kolor (Picayune, MS), (601) 798-4229 or www.houseofkolor.com; Devilbiss HVLP, gravity-feed spraygun, from ITW Finishing Systems (Glenview, IL), (847) 724-7500 or www.itwfinishing.com.

Illumination: ChanneLED 4 LEDs and Modular 60 power supplies, from SloanLED (Ventura, CA), (888) 747-4533 or www.sloanled.com; ESKA™ fiberoptic strands, from Mitsubishi (NYC), (212) 605-2000 or www.mitsubishicorp-us.com; and proprietary illuminator, from YESCO.

Printer: Acuity Advance UV printer, from Fujifilm Graphic Systems US (Valhalla, NY), (914) 749-4800 or www.fujifilmgs.com

Software: LightWave3D® animation software, from NewTek (San Antonio), (210) 370-8000 or www.newtek.com

Vinyl: Controltac™ repositionable vinyl, from 3M Corp. (St. Paul, MN), (800) 328-3908 or www.scotchprint.com

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

American Sign Museum Names New Executive Director

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

Graphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Ask Signs of the Times3 days ago

Ask Signs of the Times3 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Photo Gallery1 day ago

Photo Gallery1 day ago30 Snapshots of the 2024 ISA Sign Expo

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks6 days ago

Benchmarks6 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoWhy We Still Need the Women in Signs Award

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More