This month, let’s shift our discussion away from wraps – well, vehicle wraps at least. We all know how versatile – and vital – vinyl is for our shops. By comparison, vehicle wraps are a relatively new, vinyl-graphic application … or are they?

Let’s step back into vinyl’s history. Did you know that vinyl, or, more accurately, polyvinyl chloride (PVC), was invented before the 20th Century? However, it was rarely used, until Waldo Lonsbury Semon, a chemist for B.F. Goodrich Co., discovered in 1926 how to “plasticize” PVC. That year, Waldo applied for and received a U.S. patent for “Synthetic Rubber-Like Composition and Method for Making Same”.

Without delving deeply into a chemistry lesson (which I have honestly no clue about myself), let’s say this process enabled vinyl’s widespread use. Now, it’s the second-most produced plastic material in the world. And, it’s given us what I consider the biggest advancement in signmaking history. It transformed the time-consuming handpainting of signs into a nearly automated process of plotting or printing colorful vinyl rolls, many of which are formulated for specific applications – concrete floors, countertops, walls and numerous applications.

One original vinyl film was 3M’s Di-Noc, which was invented in the 1930s. It’s still one of the most commonly used films for architectural decoration. But, coming full circle, its roots are in vehicle-wrap decoration.

3M originally invented the material to decorate exterior, automotive body panels. Most commonly, it was used to decorate “woodie” station wagons. When they were originally manufactured in the 1930s, these cars were built with real wood panels. However, as steel-body fabrication became the preferred carmaking method, wood-paneled cars disappeared.

However, in the 1950s, Ford and Mercury continued to offer “wood-panel” vehicles. But, instead of wood, they were decorated with simulated-wood, Di-Noc panels. And I thought vehicle wraps weren’t invented until the 1990s!

Di-Noc remains a popular film for creating custom flooring, ceiling wraps, countertops and other interior decorations. The film is offered in such finishes and textures as metallic silver, wood-grain and leather. Having originally been produced for the automotive industry, its durability matches cast vinyls, such as 3M’s 1080, Orafol’s 975 or Avery’s Supreme 900 vehicle-wrap media, we use today. They’re designed to withstand the rigors of daily use in a commercial or residential environment.

Advertisement

Into the vault

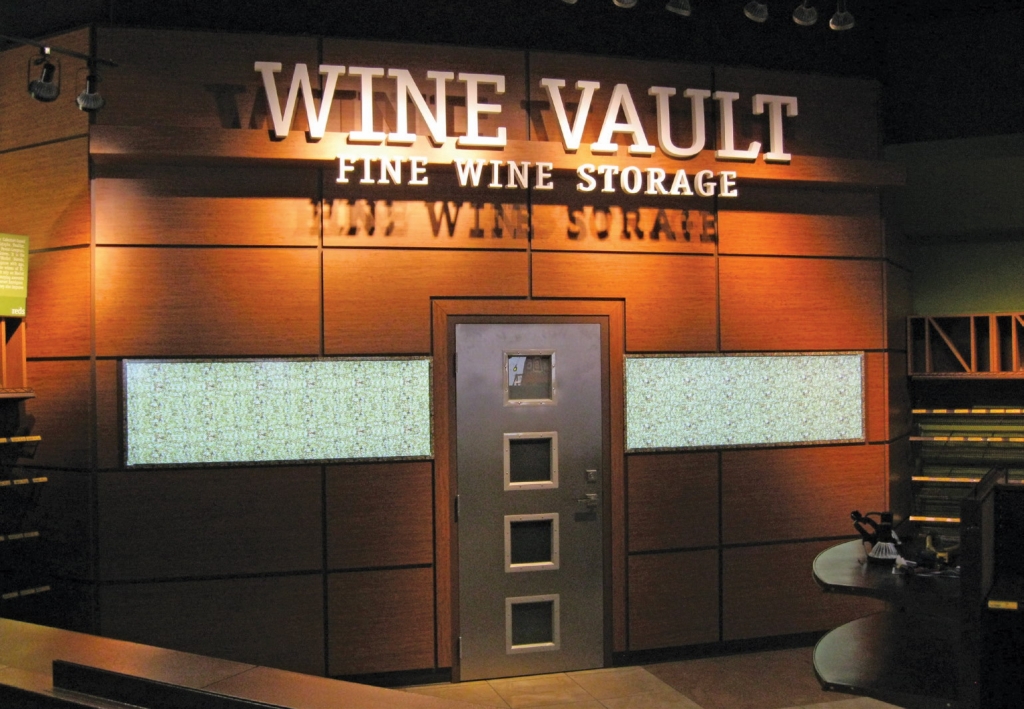

We’ve used Di-Noc on several Florida projects; one particularly memorable job involved a custom, segmented-wall concept for ABC Fine Wine & Spirits stores. They operate more than 165 Florida locations, and they understand the need for durable architectural graphics. Inside its stores, ABC created a special room, known as The Wine Vault, which provides a temperature- and humidity-controlled environment (normally in the 58-65ºF range) where customers can purchase high-end bottles of wine stored in optimum conditions. Nobody wants to select a $500 bottle of Napa Valley’s finest from a grocery store’s shelf, right?

So, obviously, this room’s exterior must look elegant and inviting, while also meeting budget and a quick-turnaround construction schedule. The vault room’s 13-ft.-tall entry wall features 33-ft.-wide, angled side walls. After having discussed the project with them, we decided to create a segmented wall that simulates the appearance of thick, wood panels, which attached to the drywall with a 1-in. border gap around the sections. This allowed the dark-brown wall’s color to show through.

Imagine the fine finish work and cost required to construct and install more than 40, 24 x 48 x 1-in., solid-wood panels to those walls! Enter Di-Noc FW 796 (FW stands for fine-wood finish) and several sheets of 1-in.-thick, MDO signboard. Media1 designer Tim Justice designed the artwork with CorelDRAW 14, and prepared the .EPS production files that were sent to our 5 x 10-ft. MultiCam 3000 CNC router table. We cut each panel to shape, and included four stud holes on the backs of each for installation ease in the field.

After having completed this step, Scott Schmierer, Media1’s production beast, began the wrap process. Numerous pieces were needed to assemble 46 panels, but the process was easy: wrap the face of the smooth MDO board, including the sides’ full depth, and then wrap behind the boards and create a ½-in. seam behind them.

We wrapped behind the panels, rather than just down the sides, for two reasons: the side edges present the greatest point of stress for the vinyl, and they’re just raw-cut plywood. Even after sanding, it’s not the optimum surface for vinyl adhesion. But, the backs of the MDO boards are nice and smooth, and will hold perfectly and eliminate the stress points.

Scott spent just a few hours wrapping all the panels, and we had beautiful, thick, wood-grain panels ready for installation in less than one day! Because the Di-Noc material contains air-release, adhesive technology, the job was pretty easy.

Advertisement

Onsite installation was equally simple. After we’d completed a thorough survey of the new Vault walls, Scott printed out a full-size, paper pattern that showed nothing but stud-hole placement for all the panels. One of our installers, Charlie Kallberg, taped the pattern to the walls, drilled four holes per panel, and threaded 3/16 x 1.5-in., aluminum studs into the back of each panel. Then, he added some silicone adhesive and pushed the panels flush to the wall, and we were done inside of one day.

To complete the project, we also installed two, 2 x 6-ft. sign cabinets with internal illumination provided by Ecoxotic Panoramic 3D 0.72W white LEDs. Media1 also printed acrylic face panels, which we slid into custom alcoves that the general contractor provided on either side of the steel entry doorway. The main-ID sign comprises a lightweight, aluminum raceway box, which we bent to shape with a 10-ft.-long, manual press brake, that’s wrapped in Di-Noc FW 796 to match the wall panels. On the box, we mounted routed, 2-in.-thick, painted-white, HDU letters. We sold the entire project for $17,000; we provided years of effectively themed branding for a fraction of what real, painted wood would’ve cost.

The client was thrilled with the Wine Vault’s new look, and we’ve since completed three more Wine Vault locations. Plans to convert all of ABC’s Wine Vaults are in the planning stages. This was a great example of how expanding your product line creates more satisfied customers – and more profit

Tip Sheet2 days ago

Tip Sheet2 days ago

Business Management1 week ago

Business Management1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal3 days ago

Real Deal3 days ago

Editor's Note1 week ago

Editor's Note1 week ago

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago