The year is 1847. Emily Bronte is writing Wuthering Heights, a tragic love story. A quill and a solid, black pigment called India ink are her only means of documentation. The ink’s lampblack and gum or glue mixture allow Bronte to record her inspiration permanently on parchment. Each stroke of her ink-dipped quill brings her closer to completing a work of art that will entertain and inspire generations of literary minds.

In the mid 19th century, quills and high-quality, permanent writing inks were essential tools for producing literary works of art. Today, digital-printing equipment and high-quality, compatible printing inks combine to create durable, lightfast applications.

In general terms, an ink is any liquid or viscous (i.e., sticky) substance used for writing, printing or drawing. Ink composition and consistency may vary. However, all ink types are made up of two rudimentary components: a colorant and vehicle. A colorant is also known as a pigment or dye, while a vehicle is defined as a liquid (i.e., water, alcohol or another solvent) into which the colorant is dispersed. The most common ink types are used for writing, drawing and printing.

Before the development of colored printing inks in the late 18th century, the first printing inks used were made from finely powdered black soot called "lampblack," and mixed with either varnish or boiled linseed oil. To remain on the cutting edge of colored printing-ink technology, early 19th-century developers introduced a variety of pigments for use in the manufacture of colored inks. Later, varnishes and mineral oils were used as primary ink vehicles.

It wasn’t until the 20th century that ink manufacturing became the process it is today. In summary, the process involves creating a pigment and vehicle mixture, grinding the mixture in a milling machine, then adding driers to absorb the mixture’s moisture.

Although printing inks have been around for centuries, inkjet printing inks are less than 10 years old. In many cases, wide-format, inkjet-printer manufacturers specially formulate inks to match a machine’s printhead technology, speed and overall composition. Printer manufacturers also provide coated substrates to work in conjunction with their inks, allowing end-users to achieve the best print results possible. As such, we’ve outlined the advantages, disadvantages and uses of dye, pigment and sublimation inks.

Color to "dye" for

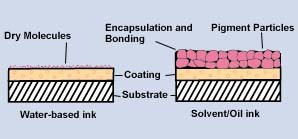

Inkjet printing inks include water-, oil- or solvent-based dye inks. In such inks, dye molecules are dissolved into an ink vehicle such as water, alcohol or another solvent and remain unsuspended. The color and vehicle compound is then ejected by an inkjet printer onto a substrate. How well a substrate absorbs the ink depends upon the substrate’s coating.

ANAgraph Inc.’s (Costa Mesa, CA) Project Manager Jim Myres explains that a dye is made up of single molecules that reflect light. Myres says, "If you print a dye-ink image onto a paper substrate, the image’s color will appear bright and intense." However, although dye inks produce vibrant colors, they are not colorfast, meaning, they’re not outdoor-durable.

On the subject of dye-ink outdoor durability, Roland DGA Corporation’s (Irvine, CA) Sales Manager of Specialty Markets Brian McLeod says that Roland is doing less and less business with dye-based inks. The reason? A print’s permanence is more important to sign-makers than exact color matching. He explains, "The longevity that is achieved using a pigment ink outweighs any minor color-gamut advantages offered by a dye ink." McLeod says that even the fine-arts market, which is primarily concerned with color reproduction, is changing to pigment inks because of dramatic improvements in color gamut and longevity. Roland DGA Corporation

According to Myres, a water-based, dye-ink print without lamination will not survive outdoors for more than two to three weeks. On the other hand, a solvent-based dye ink with a large amount of resin is capable of surviving outdoors longer.

Resins are commonly used in inks and other liquid materials to make them more adhesive. Myres explains, "A resin is a plastic, so to speak, which coats the ink and dries hard, making it more outdoor durable. A dye ink with resin is more desirable [for outdoor use] than a dye ink without resin."

Pigment: a Popular Choice

Pigment inks are preferred over dye inks for durability, lightfastness and UV-resistance. And, with advances in pigment technology, Myres believes that pigment inks are nearly as vibrant as dye inks. While dye inks are used to produce short-term applications, pigment inks are used to create long-term applications where color-balance longevity is expected.

Unlike dye inks, pigment inks must contain a certain amount of resin. About this, Myres says, "Without resin, pigment inks won’t stick to a surface — they’ll smudge. If a pigment ink is heavily coated with resin, the ink could last [outdoors] up to three to five years." Myres also says that substrates and the environment play an important role in determining a print’s outdoor durability.

Depending upon the equipment and ink manufacturer, pigment inks are either oil-, solvent- or water-based. As is the case with solvent-based dye inks, solvent-based pigment inks may be more outdoor durable because they contain a high number of resins.

Myres summarizes that pigments are heavy particles that can only be suspended in a heavier vehicle such as solvent, which contains a large amount of resin. These particles are finely ground, allowing the pigment to remain suspended in the ink vehicle, undissolved. In a poorly manufactured ink, pigment particles settle, requiring constant stirring. Water-based inks, for example, are particularly susceptible to pigment settling. Oil and other solvents are recommended vehicles for producing high-quality pigment inks.

Dr. Ray A. Work III, DuPont Inkjet Enterprise’s (Wilmington, DE) new-business-development manager, places San Diego-based ENCAD Inc. at the forefront of water-based, pigment-ink technology. In his article "Weatherability and Inkjet Inks," he writes that in June 1996, |2127| began shipping its Graphic Outdoor (GO) Matched System

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery2 days ago

Photo Gallery2 days ago

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks7 days ago

Benchmarks7 days ago

Women in Signs1 week ago

Women in Signs1 week ago

Photo Gallery1 week ago

Photo Gallery1 week ago

Women in Signs1 week ago

Women in Signs1 week ago