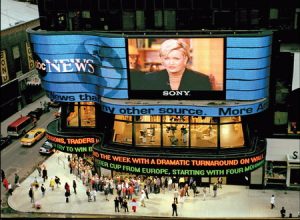

As a media façade, the ABC Times Square Studios’ LED display is a sight to behold. Nine, curvilinear, horizontal, LED video ribbons undulate around the facade’s front. Home to ABC’s Good Morning America, the building presents what seems to be a gigantic TV screen that displays network news and upcoming program and entertainment previews. Actually, the display, the only LED sign in the world that’s integrally involved with a major-TV-network program, is trailblazing the future of media-façade-based “performance signage.”

Easily seen throughout Times Square, the display broke ground as a media façade, a term that describes an LED video display that completely covers a building’s front cladding. Media facades now proliferate on Times Square to capitalize on the area’s advertising clout.

A precursor to media facades

Originally created in 1999 by its corporate parent, the Walt Disney Co., the ABC Times Square Studios’ LED spectacular is one of the area’s oldest such displays. Having beamed more than 70,000 hours of news and entertainment for eight years, the screen has recently been updated by D3 (Rancho Cordova, CA), a full-service LED video-display firm that designs and fabricates high-definiLED video displays.

D3 LED screens also appeared recently in several other Times Square sites, such as a display replacement for the Armed Forces Recruiting station, the exterior displays on M&Ms® Retail World (see ST, October 2007, page 90) and Ripley’s Believe It Or Not Odditorium (see ST, August 2007, page 90).

Initially built by Multimedia LED (Rancho Cordova, CA), the integrated LED display was divided into nine, separate, horizontal, LED ribbons, each approximately 133 ft. long, that extended lengthwise across the building. The first seven, full-color ribbons boasted a 50mm pixel pitch and formed a video-ribbon screen across the front of the building.

Advertisement

To enhance the display’s visual appeal, a SONY JumboTron LED videoscreen was embedded within the bigger Multimedia LED screen. Below that, the text-feature band briefly summarized the story behind the video image. The lowest ribbon broadcast sports news, and the one above that broadcast news headlines.

To facilitate the ribbon’s unique shape, NYC-based Landmark Signs built a curved, steel, interlocking frame that connected it to the building façade. Landmark built it in New Jersey, disassembled it and re-assembled it in Times Square.

“Once the full marketing value of the ABC LED display was understood by the Times Square advertising community, it became a springboard for many other LED video spectaculars [HSBC, Pontiac, Wrigley’s, LG, Samsung, etc.],” said George Pappas, a D3 founding partner who’s currently in charge of operations and manufacturing, and a former project manager of the original Multimedia project.

Having witnessed the upgrading of other displays, such as Coca-Cola (in 2005) and Budweiser (in 2007) and the addition of new, full-color, high-definition screens (Chevrolet, Pontiac and Prudential), the Disney Co. decided to upgrade the original ABC Times Square LED display.

During the summer of 2007, to prepare the ABC building for the new LED display, the original LED sign was stripped, one ribbon at a time, to its bare, steel frame. Having removed the original LED segments, Landmark retrofitted the new D3 LED modules (WS-10 units) onto the existing steel frame, from the bottom up, using the same LED-module connection points that held the first LED display in place. At least 3,551 D3 LED modules, each 3.5 in. (8 pixels) wide x 3.25 ft. (100 pixels) tall, replaced the original LED screen modules.

Advertisement

An icon is re-installed

The unique sign design encompasses huge glass studio windows that separate the seven ribbons above and the two below. Tony Calvano, Landmark Signs’ principal, said replacing them entailed careful planning. “During our swap out and replacement of the ABC LED modules, we started at the bottom and worked our way upwards. By the third ribbon tier, we were above the studio windows, which meant we had to protect each studio window segment as we worked above it,” Calvano said.

To protect the windows from welding sparks and dropped debris, Landmark draped and rigged a fireproof, impact-resistant tarp across the windows, below where they were replacing each ribbon of the modules. Daily, the crew set the tarp under the workspace in the morning and removed it at the end of the day.

Because of its iconic presence, the original ABC sign operated while it was retrofitted. Selectively, each old LED ribbon was turned off as its new module was installed.

Calvano said the project began with the most difficult part, the tight, curving, 3.5-ft.-radius corner of each ribbon: “The LED modules on the inside radius curve had to fit seamlessly. Then, by working from the radius outwards, we installed the rest of the ribbon, going north to the ribbon’s edge and then south to the other edge of the display. As we moved from section to section, the tarp below followed us, covering that section of studio glass. Once we perfected the radius-curve insertion technique, we did this with the other eight ribbons. All together, we replaced the entire display in about two and a half months.”

Advertisement

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery5 hours ago

Photo Gallery5 hours ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago