In contrast to other light sources, neon can be dimmed or flashed without affecting its lifetime. Even after the neon tube survived the second industrial revolution — the digital one — without major changes, dynamic light effects created with neon have closely followed the pace of time.

In this month’s edition, I’ll put some flashing lights on contemporary neon controls and try to chase some incompatibilities that have evolved from the semiconductor age to neon installations.

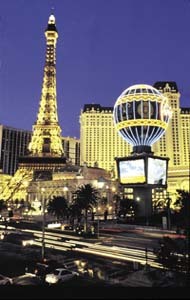

The first electric signs flashed on and off to gain more attention (Fig. 1). The switchboard, which controlled different sign segments, was operated manually, but very soon, the operator was replaced by an electric motor, which drove a camshaft for operating the switches — like in a musical box.

Today, this type of switching device is still widely used for simple animation. Such flashers are usually designed for line voltage, so each sequence within the sign (Fig. 2) needs its own transformer. High-voltage animators, which use a single transformer for the entire sign, are also available, but they present other technical problems.

Curiously, Jacob’s-ladder-like devices and thermal relays, such as from a car’s directional sign controller, have been used to flash neon signs. Further, some installations have used combustion-engine, spark-plug rotor and distributor systems.

The modern age

In modern times, mechanical switches nearly have become obsolete with the development of new power semiconductors. A semiconductor relay, or solid-state relay, which has no moving parts, is widely available in several sizes. Internally, it comprises two silicon-controlled rectifiers (SCRs) and a circuit, which provides a control input isolated from the power side. For more information on how SCR controls work, refer to books on electronic power control gear engineering.

The SCR device won’t conduct electricity normally when power is applied. When the SCR control terminal (called "gate") receives a short electrical pulse, the SCR will conduct electricity like a closed switch, as long as current will flow through it. It will reset to its original state only when the current flow is zero.

On a DC supply, the SCR can be switched "on," but never off again, as direct current will continue to flow until the circuit breaker is hit. Now, our power line feeds alternating current, and, for change of polarity, the current has to go through zero somehow. This very short time, during which no current flows, is enough time to reset the SCR into a non-conducting state.

Consequently, to maintain the SCR switch in the "on" position, the gate pin must receive a start pulse in every cycle period of the alternating current after the current has crossed zero.

Two SCRs are connected together — with one in reversed polarity — so the relay will work in both half cycles of alternating current. A back-to-back SCR with a single gate is called a "triac".

With neon transformers, we may run into problems because of their inductive characteristic; the line current is delayed relatively to the voltage applied. To avoid switching "on" the SCRs at the wrong times, special trigger circuits are necessary for inductive loads.

The control side

Semiconductor relays are available with different control inputs. In most cases, the input represents the load of a single LED, so any low-voltage (3-24V) DC, low-milliamp (2-20mA), transistor-transistor logic (TTL) or computer-output-control signal is perfect.

Many small kits (designed for the electronics hobbyist and model craftsman) blink, flash, chase or spell LEDs. You simply connect the semiconductor relay outputs to the neon transformers, and the relay inputs instead of the LEDs, accordingly. Computer controls offer no limits. Thus, depending on your skills, you can make or buy the hardware and software to drive the semiconductor relays.

Needless to say, electric safety is a must, and observance of all parts of the National Electric Code (NEC) is obligatory.

Dimming

Neon and cold cathode can be easily dimmed — a huge advantage over fluorescents and HID. Dimming is achieved by decreasing the average power going into the lamp. For neon, this can be achieved by lowering the supply voltage — using a variable autotransformer or Variac

Tip Sheet3 days ago

Tip Sheet3 days ago

Business Management1 week ago

Business Management1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal4 days ago

Real Deal4 days ago

Editor's Note1 week ago

Editor's Note1 week ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago

Women in Signs4 days ago

Women in Signs4 days ago