Just a few years ago, the digital-printing and sign markets were all abuzz about the first solvent-inkjet printers. Finally, the industry saw graphics that could handle the sun and the elements without lamination. Now, all the talk is about UV printers that can image onto rigid substrates of varying thicknesses.

Well before 60-in. solvent inkjets hit the market, an innovative designer and his engineering team introduced the Salsa, a grand-format printer. This was really the first, successful, solvent inkjet, but the wide format and high price kept the name fairly well hidden, except for those few in the billboard business.

Fast forward to 2001, and that designer, James Gandy, and the founders of the Canadian company Signtech, founded Gandinnovations. Their goal was to deliver grand-format printers that could produce outdoor graphics while maintaining vibrant colors and high resolution.

The result is the Jeti line of grand-format printers. Their aim has been to produce printers that are not only wide, but also fast, without sacrificing image quality. In recent years, they've expanded into the UV and dye-sublimation markets. They now offer a family of giants that can satisfy the needs of any business that requires size, speed and quality, particularly high-volume shops.

The product line

The Jeti family includes four products. The 5000 and 3300 are both solvent printers that target the billboard, fleet-graphics, theatrical and window-mesh markets. The 3150 flatbed printer, the UV family member, can handle numerous, interesting applications. Finally, the 3300 Dye Sub, one of the newest models, targets the sublimation-transfer markets – in a really big way. We'll discuss some specifics about each model shortly. Before we get into that, we want to talk about the printers' commonalities.

All of the Jeti printers use the same Spectra-supplied, piezo-electric, inkjet-head technology. The 300-dpi Spectra heads, some of the most rugged on the market, are designed to handle inks that use large pigments. This allows the printers to produce well-saturated, bright colors. Using multiple colors can produce apparent resolutions of 600 dpi and up to 1,200 dpi with some of the Jeti family.

The innovative ink system is common to all Jeti printers. Working with heavily pigmented solvent inks can really wreak havoc on an ink system. Clogged heads can cause ink flow to cease and thus cause problems, even when the clog is cleared. The Jeti printers incorporate an ink-bypass system that ensures ink circulation even if an obstruction is encountered.

Advertisement

Speaking of clogs, their "smooth ink flow" feature is designed to prevent dropout and blockage. Finally, the ink system, which uses both a high- and low-vacuum system, removes air bubbles from the ink as it passes into the heads. The low-vacuum feature keeps the ink suspended in the heads. All together, this system ensures reliable ink flow that's as maintenance-free as possible.

The printers' power supplies can handle voltage fluctuations between 200 and 240 volts. Additionally, they use approximately one third the power of other printers in their class.

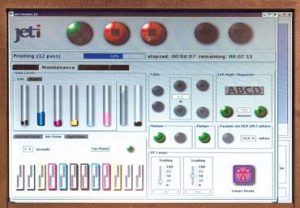

All of the Jeti printers also feature a unique user interface (Fig. 1). This totally graphical system is very intuitive and easy to use. You can choose various popular RIPs to support the printers. The RIPed images are then sent to the printer and can be stored on the console's 80MB disk. The images appear as thumbnails, and numerous image manipulations can be performed. Crop, rotate, mirror and nesting are just a few. All roll-to-roll printers are available in dye sub.

The Jeti 3150 UV flatbed

The Jeti 3150 flatbed (Fig. 2) uses 24 Spectra heads, which allows the printer to run in a 4-, 6- or 12-color combo. In the 12-color combo mode, the apparent resolution is 1,200 dpi. As a flatbed printer, it's built for such rigid materials as metal, plastics, corrugated board, foamboard and more, but it can also print on vinyl, canvas, paper and fabrics, as long as it's in sheet form and doesn't exceed 120 3 60 in. (3.048 3 1.52 meters).

To print on colored surfaces, white ink is available as an undercoat. Also, a topcoat can be applied to double the image's life. UV inks will last one to three years without a clear protective top coating. With the coating, the life extends two to six years, based on location. The prints are spectacular with a vivid color palette.

The Jeti 3312 Dye Sub

The Jeti 3300 roll printer uses 12 Spectra heads and prints at 300 dpi. Using its unique 4/6 color combination, you can achieve up to 600-dpi apparent resolution. The four-color operation sets the production mode speed at 645 sq. ft./hr. (60 sq. meters/hr.) or best mode at 485 sq. ft./hr. The six-color mode runs a bit more slowly.

The printer's beauty is that it uses dye-sublimation ink that works best on at least 50% polyester-type fabrics. The dye-sublimation process requires you to print on a medium that will then be transferred to the fabric via a heat laminating press (not included in the pricing). The roll substrate size is 10 ft. 9 in. wide (3.3 meters).

Advertisement

The Jeti 3312

The Jeti 3300 is the same resolution, size and speed as the 3300 Dye Sub. The difference is the printing substrates. Reinforced vinyl, pressure-sensitive vinyl, canvas, fabrics, mesh and paper are the printing materials rated for this machine.

The Jeti 5000

This roll-feed, solvent printer can handle media widths up to 16 ft. 8 in. The media roll can be up to a foot in diameter with a 3-in. core.

This six-color printer uses 18 Spectra heads. In the best-quality mode, it can achieve a speed of 485 sq. ft./hr. In production mode, it screams at 750 sq. ft./hr. As a six-color machine, it has an apparent resolution of up to 600 dpi. Substrates rated for the 5000 include reinforced vinyl, pressure-sensitive vinyl, canvas, fabrics, mesh and paper.

Because of the printer's large size, the included roll lifter is designed to fit against the back of the Jeti printer. Once the roll lifter is loaded, with the media positioned on the ground, one operator can install the roll on the printer. The casters make it easy to roll around anywhere in the shop. The roller uses the printer's internal air pressure to raise and lower the substrate rolls.

Advertisement

The printer's weight, 12,000 lbs. uncrated, may be intimidating. The Jeti 5000 is 72 in. tall 3 51 in. wide 3 290 in. long (182 3 130 3 736cm) and uses 220-240V single-phase, 50/60 Hz. Also, you need at least 100 psi and up to 150 psi air.

Gandinnovations' claim to fame is an extremely long head life using Spectra heads. The rest of the engineering is built to last in a production environment. High volume, high resolution and versatility make these products worth exploring.

Key Information

Gandinnovations

941 Isom Rd.

San Antonio, TX 78216

210) 344-9566

Fax: (210) 344-9569

www.gandinnovations.com

Contact: Kurt Hixson

Company Profile: Gandinnovations, founded in 2001 by a group of engineering veterans, produces grand-format printers designed for the production floor. They are tooled for the sign and screenprinting industries.

At a Glance: Gandinnovations' Jeti line of grand-format printers produces outdoor-durable graphics with speed and high image quality.

Photo Gallery6 days ago

Photo Gallery6 days ago

Tip Sheet2 weeks ago

Tip Sheet2 weeks ago

Ask Signs of the Times1 week ago

Ask Signs of the Times1 week ago

Paula Fargo3 days ago

Paula Fargo3 days ago

Real Deal5 hours ago

Real Deal5 hours ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Women in Signs1 week ago

Women in Signs1 week ago