Sign installers commonly handle the field wiring of remote neon letters and exposed luminous tubing. In past columns, we have sidestepped this more advanced skill in order to concentrate on the basics.

Now, within this new series, we will begin tackling the electrical requirements and issues that deal with field-installed neon.

To discuss field wiring, we must transform our minds. We are no longer primarily signmakers. We must envision ourselves as commercial electricians. Why? Because the National Electrical Code (NEC) prohibits installing a display with 1,000 or more volts in anything but a commercial location.

Where to begin?

For this series of articles, we’ll assume we meet the criteria of "qualified persons" as defined by the NEC, have passed a state electrical examination and can legally pull the municipal electrical permits required to install branch-circuit wiring for this display from the panel box through the last electrode. Consequently, we can focus on only technical issues and exclude prerequisite governmental and testing issues.

Our first task in this project is to run branch circuits from the distribution panel (breaker box) to the sign location. This is the sign-branch circuit. A simple, 120-volt branch circuit has three conductors (hot/black, neutral/white and green/ground). This simple branch sign circuit can supply no other load.

Advertisement

This circuit cannot power a cash wrap or display lights for the windows below. The sign circuit supplies only the sign.

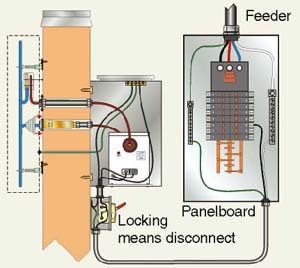

Now here’s a nice trick. All sign circuits must have a minimum 20-ampere rating. However, because we are now addressing neon, that circuit can be increased to 30 amperes. Understanding this code provision can significantly reduce cost. $image1

More allowable amperage means fewer overall circuits. The branch circuits can be wired to 80% of their load. A 20-ampere circuit can be loaded to 16, while a 30-ampere circuit can be loaded to 24. The code states, "Where a branch circuit supplies continuous loads, the rating of the overcurrent device shall not be less than the noncontinuous load plus 125% of the continuous load." A continuous load carries a maximum current for three hours or more.

The NEC allows using one circuit instead of running two, 20-amp circuits for three normal power-factor, heavy-duty, outdoor, 15,000V/60mA transformers. This saves us a breaker, a panel-box position (which can be golden) and also the additional conductors (copper = $) needed to create a second branch circuit.

There’s another plus. Commercial applications generally incorporate electrical metallic tubing (EMT). Conduit costs money — in both time and materials. Quite simply, fewer circuits require less conduit, which reduces installation time (labor).

What does it take to apply this code rule?

Advertisement

First, determine the total input current (amps) required for a given project, then meet with the general electrical contractor at the site. To calculate input amperage, total the input amps on the metal tags located on each transformer. I simply turn to the transformer section of my Glantz catalog and add up the input current (amps) of the transformers I’ll be using.

To make this work, do two other things: Install a 30-amp overcurrent protection device (breaker), and use #10 conductors (wire) for the branch circuit. Remember, this means that all primary conductors in this branch circuit are #10s, and it includes a #10 equipment-grounding conductor, because #12s are utilized only in circuits of 20 amps or less.

For the sign industry, #10 solid copper THHN/THWN — our conductor of choice — is less expensive, easier to pull and rated for both wet and dry locations.

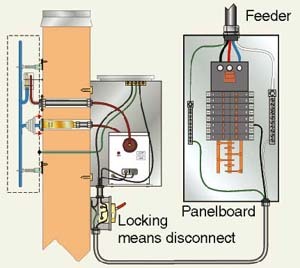

How clean is the neutral? $image2

These high-inrush motors and power start-ups can cause today’s neon power supplies to trip. Because you’re working from the distribution panel (breaker box) to the sign location, this is the perfect time to ensure that the neutral for the sign circuit is dedicated only to the sign load and clean of this inrush equipment.

Six-ft. disconnect

Advertisement

Six feet is the normal contracted distance for this circuit to transition to the first transformer. Preceding the equipment (transformers, furnace system, air handlers, etc.), the trade and code say to install a disconnect. The maximum for flexible metallic conduit in grounding utilization just happens to be 6 ft.

The big issue here is the disconnect. In a remote skeleton neon or channel-letter installation, the glass or letters are on one side of a wall, and all the transformers (which include their secondary feeds) are mounted on the display’s backside.

We should all know a disconnect is required for each sign and outline-lighting system, and the disconnect must be within sight of the sign or outline lighting it supplies. However, in a remote channel or outline lighting situation, in which any of the sections aren’t readily seen, a simple snap switch (refer to FPN: 404.14 for ratings of snap switches) in a handy box does not comply.

To rephrase this important issue, a switch on the side of a transformer, a switch mounted in a handy box breaking the primary feed on the back wall, or a slide switch mounted on a weatherproof Bell Box does absolutely nothing to meet the code requirements. The code says, "The disconnecting means shall be designed so that no pole can be operated independently and "shall be capable of being locked in the open position" [NEC 600.6(A)(2)(3)].

The Canadian Electrical Code® (CEC) concurs in 34-100(d): "Be capable of being locked in the open position where it is located out of the line of sight, or more than 9m from the sign."

There are many reasons for these mandates. The most important reason is safety. Quite a few fires have occurred because a sign electrician left a project and, during his absence, the client energized the display without understanding the consequences. If a lockable disconnect had been installed, this wouldn’t have happened.

Realistically, knowing this segment of the code has been honored provides great confidence when wiring or maintaining such a sign. Just knowing that you can pull down a lever, slap a lockout device through its tabs and secure it off with a padlock provides peace of mind.

Business Management1 week ago

Business Management1 week ago

Women in Signs1 week ago

Women in Signs1 week ago

True Tales2 weeks ago

True Tales2 weeks ago

News2 weeks ago

News2 weeks ago

Editor's Note5 days ago

Editor's Note5 days ago

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks ago

Line Time1 week ago

Line Time1 week ago

Product Buying + Technology6 days ago

Product Buying + Technology6 days ago