Digital Printing

EFI Vutek

This printer offers flexibility for specialized applications.

Published

16 years agoon

An interesting phenomenon has occurred in the flatbed, UV-cure, print-machine market. Early printers caught everyone’s eye because of the ink’s ability to adhere (print) onto almost anything. This ink adhesion, applied in conjunction with the print machines’ large, flatbed tables (equipped with elaborate, vacuum-type, hold-down systems to hold flat media in place), ensured that durable, UV-stable images could be imaged on common, flat media – plywood, foamcore boards, sheet aluminum, some types of plate glass and more.

Most early flatbeds, at least the expensive ones, were designed to handle 4 x 8-ft. media, the most common size. You were out of luck if your customer needed something longer. Flexible media, generally, required another print machine, although a few flatbed owners tried cutting their flexible media to size and printing it on their flatbed. This doesn’t always work out, but it’s the source of the phenomena.

Rigid media comes with its own set of headaches, and finding dry, humidity-free storage is the first one. Nonetheless, rigid media, in fixed sizes, arrives in boxes, so it’s easy to grab a blank, slap it on the table, fire up the vacuum and punch “print.” Loading and unloading media can be a bottleneck, especially if the printer was fast (a relative term).

Soon after manufacturers introduced flatbed printers, they logically designed and installed roll-to-roll, media-print systems on the flatbeds, to offer the best of both worlds. (Machine marketers called them “hybrids,” stealing a spin word from the auto industry.) With such a versatile printer, signmakers could print on rigid boards or roll media. End of story, right? Not exactly, because your print-machine buying decisions should be based on your customers’ wants.

At first glance, UV-cure ink appears to be the greatest stuff in the world – after all, it sticks to glass, so no problem with banner material and adhesive-backed vinyl, right? Well, yes, if the UV-cure ink is designed to be flexible. The first crops of UV-cure printers weren’t. They were designed to print on rigid materials, which aren’t meant to flex. Once it’s applied, flexing such ink may cause it to crack or flake. It’s all about the ink’s polymer type and mix.

AdvertisementIf your customers are looking for flexible-media solutions, then a hybrid UV printer might be the wrong solution. Some systems used a one-type ink for both rigid and flex media, which could allow you to print and hang a banner (that wouldn’t be snapping in the wind); these will also image on adhesive-back vinyl applied to rigid signs, but, unless you change to a more flexible ink, forget about vehicle wraps. The bends are too tight.

Does this mean you have to give up UV-cure ink’s benefits? No, because ink chemists have stirred flexible polymers into their newer blends, causing manufacturers to develop roll-to-roll, UV-cure printers.

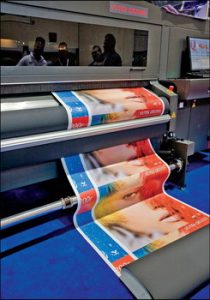

Here, we’re examining EFI’s Vutek QS3200r UV-cure printer, a remarkable machine that offers blazing speed, roll-to-roll operation and flexible inks. While originally positioned for high-volume production shops, the printer has recently been repositioned to allow mid- to high-volume shops a point of entry into the roll-to-roll UV market, so this review will interest the high-volume production shops – or those who are looking to expand their market.

Smaller shop owners should read on, however, because we expect to see more roll-to-roll, UV-cure printers come to market.

Why not rigid?

Last year we wrote about the Vutek QS3200, the firm’s traditional, UV-cure printer. It was designed to handle rigid media, but had roll-to-roll print capabilities. At first glance, it would seem to cover everything. It had rigid and roll options, a 126-in. print width and speeds up to 900 sq. ft. per hour – so why would EFI Vutek build and offer the QS3200r, a less versatile printer?

Specialization.

AdvertisementThe QS3200’s extensively flexible ink is designed to bend. It works with banner material, adhesive-backed vinyl and, get this, fabric. It also images on static cling, paper-based media and backlit films. It’s ideal for bus and vehicle wrap applications. The inks are very vibrant, and the printer produces an expansive color gamut. We’ll have more in a minute.

Do everything?

Signshops may try to build everything, but it takes deep pockets, versatile craftspeople and a superb sales and marketing staff to get there. In truth, most signmakers, us included, specialize in vertical markets. Like you, we strive to get everyone’s business – but it’s difficult to do vehicles, banners, neon, LED, carved and sandblasted signs, channel letters, engraving … and so on. We all have our niche markets, but, interestingly, the big guys probably specialize more than us little fish. They can afford to.

The POP display niche screams flatbeds and banners, as we said above – but flex is as flex does; vehicle wraps, fabric hangings, street graphics and backgrounds, all take you away from rigid media. Therefore, if vehicle wraps or large, full-color banners are your main business, choose a printer for that type work.

Why not solvent?

Solvent-ink-based printers provide flexibility and durability. They are less expensive, and the inks bond well to vinyl and banner material. Solvent inks also have a wide color gamut, and, properly done, prints always look good. Unfortunately, solvent-ink printers require (machine-attached) ventilation systems and waste-handling processes. This removes some of the appeal.

Fabric printing, another niche, requires a printer equipped for a dye-sublimation ink.

Expectedly, EFI Vutek recognizes the various markets and offers both solvent- and dye-sublimation printers. The UV-cure, QS3200r printer sits smack in between them. The “Q” is for quality, the “S” for speed – the “r,” we think, stands for “Really.”

AdvertisementThe QS3200r

EFI Vutek recognized the limitations of its QS3200 for specific applications and decided to introduce the QS3200r, which shares many of its forerunner’s qualities, but isn’t the same. Vutek designed, and we found, significant differences. The “r” model isn’t a QS3200 sans tables.

Like the QS3200, the QS3200r is a massive beast – its 5605-lb. weight is just under that of Cadillac’s Escalade, so don’t call a couple of buddies to help you move it. The industrial-grade machine stands 69 in. high, 232 in. wide and 67 in. deep. It prints on media up to 126 in. wide.

You’ll need 1-phase, 70A power that supplies 200 to 240V. You’ll also need dry, pressurized shop air at 95 psi/4 cfm and operating humidity (non-condensing) in the 30 to 80% range. The room temperature range is 68° to 86° F.

Image quality and speed

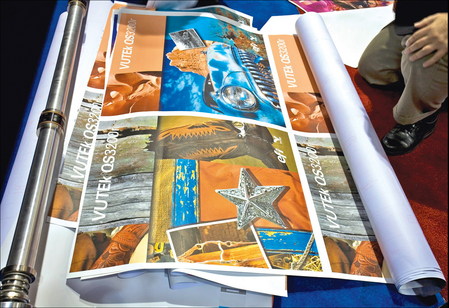

The QS3200r’s ink is ideal for bus and vehicle wraps. It works with banner material, adhesive-backed vinyl, paper-based media, backlit films, static cling and fabric. It conforms to trailer rivets and such complex curves as those found on Chevrolet’s difficult-to-wrap HHR.

The printer’s Seiko’s piezo-inkjet heads can produce 540 or 1,080 dpi resolution (Fig. 1). Its high-quality mode can produce readable, four-point text at speeds up to 900 sq. ft. per hour. It images eight colors: cyan, magenta, yellow, black, light cyan, light magenta, light yellow and light black. In two or three minutes, you can switch to a dual set of CMYK inks, in lieu of the eight-color system, and, now utilizing both sets, print high-quality, four-color images at speeds up to 1,850 sq. ft. per hour.

EFI says you’ll save on production costs because the QS3200r’s ink covers better than solvent ink.

Media handling

EFI Vutek printers are built like a tank. The same design philosophy is in the media-handling system. The QS3200r can handle what you throw at it (Fig. 2), including the substantially sized, 10-ft.-long media rolls we saw mounted. And, although its clearly not a flatbed, it will handle flexible media up to .125 in. thick. With scant exceptions, that’s pretty much anything that comes on a roll.

In addition, it offers many exceptional features. You can load two small media rolls of instead of the large one we mentioned above (Fig. 3). The software accommodates this configuration, so you can easily select and output several jobs on different width (or type) media. You can print on both sides of the media. No belts move the media (Fig. 4), and the paper path is a simple “S” shape; thus, media loading is easy (Fig. 5). Because this is a UV-cure printer, the prints don’t require post-process drying.

Service

Although EFI Vutek has a reputable and long-established, service-and-support organization, know that these printers are designed to run 24/7, and EFI is always there to help keep you going. In addition to onsite-support plans, it offers telephone, email and online support.

Conclusion

We think the QS3200r is an absolute marvel. See it run, and you’ll think you’re watching a high-end, solvent-ink printer. The images are crisp and vibrant, and the thing runs at crazy-fast speeds.

Take a deep breath, and you notice … well, nothing. There are no funky fumes.

Want to do some fabric backdrops or banners? No problem. Bus wraps and vehicle graphics? A snap. If you’re looking for a high production roll-to-roll printer, check out the QS3200r. It may not be flat, but it’s flexible.

Key Information

EFI VUTEk Inc.

One VUTEk Place

Meredith, NH 03253

(603) 279-4635

Fax (603) 279-6411

www.efi-vutek.com

Company Profile: EFI™ provides products, services and support to handle all businesses’ print needs. Headquartered in Foster City, CA, with 26 worldwide offices, EFI’s award-winning, technologies increase the productivity and profitability of commercial and enterprise printing. EFI’s VUTEk superwide, digital-inkjet printers and inks cater to mid- to-high-end specialty print shops, including signshops, billboard, banner and graphic-screen environments and commercial photo labs.

At a Glance: VUTEk’s QS3200r offers speed, roll-to-roll operation and flexible inks. It was originally positioned for high volume production shops, but EFI Vutek has recently repositioned it allow mid- to high-volume shops a point of entry into roll-to-roll UV. This printer will interest the high volume production shops – or those who are looking to expand their market.

Contact: Jane Cedrone, marketing communications mgr. jcedrone@efi.com, (603) 279-6811

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Alicia Brothers

-

Projects5 days ago

Projects5 days agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza