Digital Printing

Durst’s Rho 160 UV Flatbed Printer

A high-performance, digital-production, inkjet system

Published

18 years agoon

Wide-format, flatbed printers that can handle thick and rigid media are becoming progressively popular. We’ve seen several of these printers, and we can attest to their advantages and flexibility. Because many of these machines are set up primarily for rigid and semi-rigid media, they sacrifice the flexibility of continuous roll-feed. In addition, such printers require routine, operator intervention that can stifle productivity.

Having seen so many of these products, we pondered the possibility of a printer that addressed flexibility issues and handled the rigors of a volume-production environment. After reviewing Durst Photechnik Digital Technology’s Rho 160, we discovered such a machine exists.

The Durst U.S. name might be unfamiliar, but the company pioneered photographic technology in 1936. Its products abound in darkrooms and high-end photo labs. As the digital age emerged, Durst developed numerous laser-based products for its core customers.

Its most recent product, the Rho 160, culminates Durst’s knowledge and experience. Although the Rho 160 primarily targets screenprinting and photo-lab markets, signage and custom-graphics professionals can benefit from the machine’s features and capabilities.

We reviewed the Rho 160 at the 2003 International Sign Assn. (ISA) show in Las Vegas. Although the machine’s $465,000 price might overwhelm many shops, large screenprinting operations and industrial signshops will see a quick return on their investment due to the system’s speed and flexibility.

Specifications and ink

To say the least, we were impressed by the Rho 160. The massive machine would seemingly require a small army for operation. Surprisingly, however, one operator can control the printer.

The carefully crafted and constructed system features logically placed controls and primarily focuses on safety. Weighing 4,400 lbs., the Rho 160 is one of the largest printers we’ve ever reviewed. The manufacturer recommends a 22 x 20-ft. space to accommodate the 183-in.-wide, 97-in.-tall, 174-in.-deep (drop tables down) unit.

Power requirements include 120/208VAC 3 phase and 230/400 VAC 3 phase. In addition to handling typical power requirements for media and head movement, you’ll need to accommodate the unit’s sophisticated, UV-curing system and vacuum, hold-down system.

The piezo-inkjet printer features 360-dpi resolution, with an apparent resolution of 720 dpi. Although the Rho 160 uses only four colors (cyan, magenta, yellow and black), the inks’ vibrancy allows the system to output high-quality images. In addition, a built-in, head-maintenance system monitors the printheads’ operating condition.

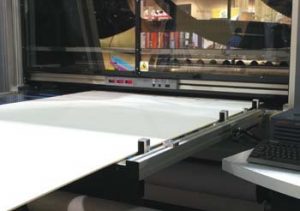

The ink system is totally enclosed (Fig. 1) and holds 2.6 gallons per color. You can refill it during printer operation — the refills come in 5-liter (a little more than a gallon) containers. The system’s only available ink type accommodates all substrates to further simplify the printer’s operation.

Proper venting is required for comfort and to expel the ozone produced during curing. The curing lamps’ UV radiation could pose a risk, but it’s impossible for an operator to get close enough to cause any problems. By taking obvious precautions and providing proper ventilation, you’ll discover that the system is extremely safe and user friendly.

We learned that ink prices range from 10-30 cents per sq. ft. (depending on the coverage), with an average of 16 cents. In addition, you don’t need to purchase expensive, coated media. As many of you know, coated media for inkjet systems is extremely costly.

The Rho 160 accepts off-the-shelf media and even low-cost papers. The inks’ ensured outdoor durability eliminates the need for lamination. Add the ability to print directly onto thick and rigid media, and you’ve eliminated a finishing step. Although the system requires a hefty, up-front investment, it can lower your printing and finishing costs.

Media handling

Durst incorporated UV-cured, solvent inks because they can print onto virtually any substrate, if the machine’s feed mechanism can handle it. Many new flatbed printers are dedicated to rigid materials. Typically, if you want to print a poster using regular paper on a flatbed, you need to cut it from a roll and line it up on the table. Durst has chosen a more flexible approach. The printer accommodates both rigid materials and roll media. Simply follow a media-loading procedure (Fig. 2).

The printer can handle rigid-material thicknesses up to 1.58 in. A roller table folds out from the front and rear to accommodate thicker media (Fig. 3). Feeding is continuous with auto-registration, and sensors check media width, length and thickness. Wood, metal, glass, stone, cardboard and numerous other substrates can be imaged.

The blank is fed from the front and emerges, dry to the touch, from the rear of the machine. As opposed to some other flatbed printers we’ve examined, the media moves from front to back, and the heads pass back and forth on a fixed axis, much like a traditional printer. During printer operation, the heads and UV-curing elements are enclosed in a protective cage, which machine operators can’t access until printing is complete.

Some media may require edge-to-edge printing, for which Durst has provided a special insert that catches the overspray and prevents it from fouling the machine’s interior. A special insert is also required for fabric substrates. Installing or removing these inserts are the only times an operator should be inside the printer.

To print banners, material doesn’t need to be cut to size, because the Rho 160 can accommodate three rolls of media. Simply fold the tables, load a roll and begin printing.

A take-up reel on the system’s backside allows continuous printing; an automatic cutter is available for cutting pieces to size. The printer can handle media widths up to 62 in. and roll lengths up to 2,460 ft. For rigid material, the unit can accommodate 12 x 30 in.

In standard printing mode, the Rho 160 can output 470 sq. ft. per hour; in high-quality mode, it produces 340 sq. ft. per hour. In high-quality mode, this equates to 55, 2 x 3-ft. posters per hour.

Software and workstation

The ability to print onto numerous substrates is meaningless if you can’t reproduce satisfactory graphics. Many printer manufacturers push their own ink and media brands to increase profits and ensure consistent results. So, if you want to print onto cardboard or wood, how can you ensure acceptable results?

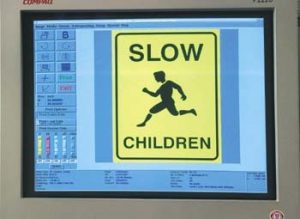

Durst has bundled a workstation and software. As a result, the printer includes sophisticated, color-calibration software (Fig. 4) that can read a set of swatches printed onto target media and adjust the printing to match the image. Here, years of photographic experience come into play.

We observed the same image printed onto numerous media types that exhibited virtually the same colors and tone. In fact, Fig. 5 depicts part of Durst’s ISA booth. Look closely; part of the model image is actually a door. Durst employees purchased a door from a home-improvement store and ran it through the printer after calibration. As you can see, it’s a perfect match.

Color matching is great, but if a small system feeds the beast, the workstation can bottleneck. The system features a workstation; however, it comprises a Compaq True-64 64-bit UNIX workstation, not a standard Windows PC workstation.

In addition, the system contains 512MB of RAM and two 18GB Ultra-SCSI hard drives (one for OS and software, the other for images). Overall, this fast system is dedicated to RIPping images and managing the printer.

The Durst-developed applications are designed to work specifically with the printer and inks to create a tightly coupled system. The software handles most of the functions required to operate the system. Ink levels, remaining media, etc. are controlled and conveyed through the software. The printer’s integral control panel primarily displays status information. The workstation serves as the printer’s control center.

The printer’s unique PostScript Level 3 raster image processor (RIP) features on-the-fly processing logic that greatly speeds print-file creation and uses minimal storage space. You can adjust contrast, saturation and sharpening without re-RIPping the image. The RIP has no problem keeping up with the system’s 470-sq.-ft.-per-hour print speed.

To further enhance productivity, the software supports a sophisticated, queue-management system (Fig. 6) that allows jobs to be sorted and prioritized by numerous factors, including media type. The queue also maintains media usage and informs operators after every job is printed.

Further, a built-in, auto-nesting feature ensures that wide media is used to its fullest capabilities, producing minimal waste. You can submit jobs as batches to separate clients’ jobs, and the software can handle automatic paneling.

Although 62 in. is pretty wide, a client may need an image that covers a wall. The software will automatically panel the job based on the media. Finally, the system features a high-speed Ethernet connection so other users can submit jobs to hot folders.

The Rho 160 in action

According to Durst, a large percentage of its customers are high-volume screenprinters. They often prototype a piece for quick customer approval and produce runs of 100-150. The manufacturer also reports that photo labs and digital printers benefit from the system.

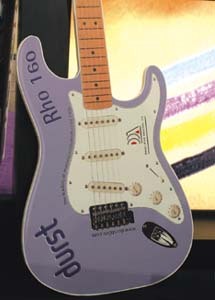

For example, images can be printed directly onto foamboard (Fig. 7), which eliminates mounting and finishing costs. Its ability to print onto fabrics means that stage backdrops also can be produced quickly and accurately.

There’s also the prototyping factor. We’ve all seen cool POP displays in stores. Now, salespeople can get full-size mock-ups in a fraction of the time, which can reduce the sales cycle.

Overall, the Rho 160 is a marvelous engineering feat. From its ability to accommodate roll-fed, backlit media, to more rigid materials like a foamboard guitar (Fig. 8), the printer offers unbelievable versatility. If you’re a large, digital-print shop or high-volume screenprinter, take a closer look at this incredible machine. You’ll be glad you did.

| Key Information |

| Report Date: May 2003 Company: Durst Dice America LLC Company Background: Durst Dice America LLC (DDA) is a manufacturer, service provider, systems integrator, distributor and developer of high-end, computer, graphic-output devices; software; LAN; and Telecom-based networking systems. In January 1999, Dice America merged its operation with Durst ACS, the U.S. distribution and service provider of Durst Phototechnik AG (Brixen, Italy). The merger brought together a recognized leader in digital workflow development, marketing and service (Dice America) with one of the world’s leading photo-equipment manufacturers (Durst AG). Contact: Ryan Fosegan, marketing communications manager Minimum System Requirements: Included proprietary UNIX front-end workstation; interfaces: Ultrawide-SCSI, Ethernet AUI-Port; fast Ethernet card (100 Mbit); RS 232. List Price: $465,000 Note: ST‘s product-review policy is that items must have been offered for sale for 30 days before the review. Add this to ST‘s typical production time, and at least 60 days have passed since this product’s introduction. New or revised editions may have come on the market during that time. |

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Ask Signs of the Times2 days ago

Ask Signs of the Times2 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks5 days ago

Benchmarks5 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoWhy We Still Need the Women in Signs Award

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Product Buying + Technology2 weeks ago

Product Buying + Technology2 weeks agoADA Signs and More Uses for Engraving Machines

-

Photo Gallery6 days ago

Photo Gallery6 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More