Design

Bluemedia Gives Phoenix Off-Premise Sign Cool “Four Eyes”

Project adds to Legends District’s considerable luster

Published

11 years agoon

Glenn Probert is a national sales executive for bluemedia (Tempe, AZ).

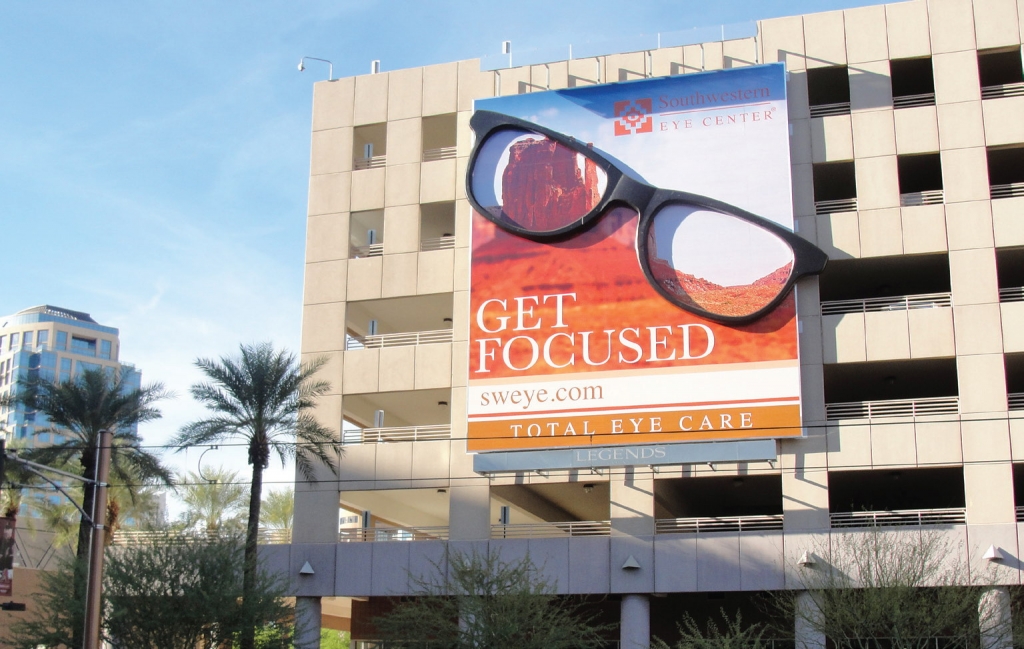

Located in Phoenix’s Legends Entertainment District, next to the city’s convention center, a new, 3D billboard promotes the Southwestern Eye Center (which doesn’t have a location in the center, but three locations that serve the Phoenix area). It exemplifies bluemedia’s dedication to strong partnerships and courageous innovation. Although displays abound throughout the Legends Entertainment District – such as our wall wrap that identifies the district (see ST, February 2013, page 53) – this billboard was the first sign in the area to fully implement 3-D design and construction.

This project evolved through collaboration between the expert staff at Legends Entertainment District, and Boyd Erickson, senior graphic designer for the Arizona Diamondbacks baseball team. Together, they developed an initial concept that would present the Southwestern Eye Center in an exciting, novel way. We’ve worked with Legends’ management for approximately two years; producing signage and promotional graphics in the six months leading up to the 2011 All-Star Game, which was held in Phoenix, became a springboard to their becoming a prominent client. They’re always open to creating new, sign-related marketing ideas. They aggressively seek new marketing opportunities, which involve many complex designs that we “reverse engineer” to recommend fabrication methods and materials.

Once they’d established the billboard concept, they hired our shop to bring it to life. Under the guidance of bluemedia’s structural-project manager, Patrick Tennant, and myself, the project advanced as Legends Entertainment District representatives and bluemedia pooled resources to develop solid, workable mechanical blueprints that created the foundation for the billboard’s success.

The master plan

The project began as a series of .PDF files; file sharing is a frequent part of collaborating with Legends. We produced the creative concepts, which Legends put through its standard, client-approval process. Using CorelDRAW® X5, we created the blueprints. Our engineering staff provided attachment specifications, which were crucial for aligning the five pieces that comprise the eyeglasses within the existing framework, which also included frontlighting.

The client asked us to work on a standardized measurement of cubic feet because they wanted their prospective clients to be able to offer 3-D design to their out-of-home advertisers. As always, the biggest challenge with an innovative project is creating a design concept that could actually be engineered. Once we determined the giant, 3-D glasses could properly float on flexible-face material without any issues, everything else magnificently fell into place.

AdvertisementThe main sign panel measures 42 x 36 ft.; the glasses, installed diagonally, span 44 ft. 10 in. The glasses were eventually constructed from ¾-in.-thick plywood, and mechanically attached to dense, sculpted, beaded-EPS foam, topped with a Polygem polyurethane hardcoat, which was applied with a spray gun. To create the appropriate density and texture, we applied the coating in layers before it was painted. The polyurethane encapsulates the plywood, and creates a very rigid and sturdy final product. To be practical with transportation and install, we split the glasses into separate, more manageable pieces, which we reassembled later during the install process. We painted the glasses with Matthews acrylic-polyurethane paint.

We transported all necessary pieces from our facility to the jobsite on a flatbed truck, and field oper-

ations manager Tug Orr and installers R.C. Gile, Ricky Saucedo, Monte Wieseman and Rick Pace devoted three days to install the sign and make sure all parts were operational.

The biggest challenge was lining up each piece with the already installed supports. The rod-shaped supports allowed the pieces to slide into place. We secured a rope-line system to the structure’s roof and used a Genie knuckle-boom crane to secure the hardware to the support rods. Many tasks were executed with flawless precision. With a structure this large, and this high up, there is very little room for error.

For all to see

First, the existing banner that occupied the spot had to be carefully removed. Then, we installed a wooden template, which we’d cut to match the shape of the 3-D glasses, to help ensure an accurate install.

Then, the installers marked 35 strategic anchor points where the frame and glasses intersected to provide optimal support and structural stability. The metal grid on the building served as a reference.

We drilled through the frame and installed custom, steel brackets attached with all thread rods. Once these points were drilled, we gently removed the template. Once we verified all anchor points had been properly placed, we installed the banner that would sit underneath the glasses.

To fabricate the banner, we printed on Ultraflex’s Normandy Pro 13-oz., matte-finish material, which was printed on our 16-ft.-long, solvent-ink HP Scitex XLJet 5. We seamed the print, which weighs approximately 40 lbs., vertically, rolled it up and placed it on a flatbed bound for the jobsite.

AdvertisementFinally, after all of this had been properly executed, the 3D glasses could be placed on top of the underlying banner, because each piece was connected individually to its assigned anchor point.

To highlight the sign in darkness, the sign frame contains a fluorescent, T5 lamp, which hangs down from overhead. Before installation, we tested the lightsource to verify its illumination worked and would enhance the sign.

The project required approximately a month from initial concept to final execution, but provides proof that bold and innovative partnerships can deliver equally bold and innovative accomplishments.

“At the Legends Entertainment District, we pride ourselves in providing our partners unique, out-of-home-advertising concepts,” Judd Norris, general manager of Legends Entertainment District, said. “We know and trust that the bluemedia team can take our idea concepts and turn them into reality.”

Equipment and Materials

Coatings: Polyurethane hardcoat, from Polygem (West Chicago, IL), (888) 446-3987 or www.polygem.com; acrylic-polyurethane paint, from Matthews Paint (Delaware, OH), a division of PPG Industries, (800) 323-6593 or www.matthewspaint.com

Crane: Knuckle-boom truck, from Genie (Redmond, WA), (800) 536-1800 or www.genielift.com

Lighting: Gooseneck downlighting with T5 fluorescent tubing, from such manufacturers as GE Lighting (Cleveland), (216) 266-2121 or www.gelighting.com

Printer: Grand-format XLJet 5, from HP Scitex (Palo Alto, CA), (800) 383-2649 or www.hp.com/scitexprinters Software: CorelDRAW® X5, from Corel Corp. (Ottawa, ON, Canada), www.corel.com

Substrates: Normandy Pro 13-oz., banner material, from Ultraflex (Randolph, NJ), (800) 368-7858 or www.ultraflexx.com; expanded-polystyrene foam, available from such manufacturers as Harbor Foam (Grandville, MI), (616) 855-8150 or www.harborfoam.com

Miscellaneous: Plywood, drills, all thread, and anchor bolts, from hardware and building-supply stores.

AdvertisementMore About bluemedia

Jared Smith founded bluemedia (Tempe, AZ) in 1998 to serve the large- and grand-format market: banners, vehicle graphics and an array of other digitally printed graphics that serve customers in the event, retail, hospitality, transit and POP markets, among others. The shop has also expanded its repertoire into illuminated, 3-D signage. Bluemedia has garnered such high-profile clients as Coca-Cola®, Clear Channel Communications and Wells Fargo, among others.

The company operates a 55,000-sq.-ft. facility that utilizes EFI-VUTEk, HP and Scitex wide-format printers, as well as an array of finishing solutions. Bluemedia has achieved G7 certification; G7 is a grayscale, color-calibration system that requires exacting color management.

For more information, visit www.bluemedia.com

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet4 days ago

Tip Sheet4 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks1 day ago

Benchmarks1 day ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines