Dimensional Signs

Abbey Rout

Lincoln Sign Co. adapts a painting into creative signage.

Published

15 years agoon

J.D. Iles is president of Lincoln Sign Co. (Lincoln, NH).

Boyd and Sharon Bush contacted us to discuss creating a sign for a new wine and specialty-food store they’d soon open in the Lincoln-Woodstock (NH) area. Nestled in the heart of New Hampshire's White Mountains, our region’s economy depends heavily upon tourism, so distinctive signage represents a key priority.

Lincoln Sign Co. had made signs for the Bushes years ago when they operated other local businesses, and we were very happy to work with them again. It’s gratifying when previous customers return, looking for help promoting a new business venture. Immediately, they wanted a carved wooden sign to hang above the storefront, but I was thrilled to learn that they wanted something unusual and visually engaging. Starting a project with creative carte blanche from the customer energizes my creative juices.

No ordinary sign

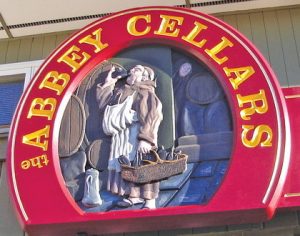

Boyd and Sharon had named their business The Abbey Cellars; discerning customers searching for higher-quality food and wine comprised their target market. They needed a strong sign design, suggestive of food and wine, that also projected an aura of style and class.

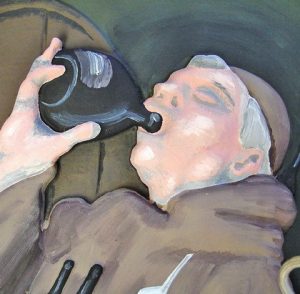

AdvertisementYears ago, their son brought a painting back from Germany of a monk in prayer; this painting provided inspiration for the Bushes’ sign and corporate identity. They wanted a sign that embodied the rich woodcarving heritage native to the White Mountains, but they also wanted something more than run-of-the-mill, carved signage. We chose burgundy for the background color, which provided a "rich" feel. I wanted dominant white lettering — not only for the sake of contrast and legibility, but also to suggest straightforward simplicity that exemplifies local signage’s traditional look.

A team effort

Because of the detailed bas-relief carving we planned to develop for the project’s centerpiece, I enlisted the help of James Booth, owner of Vector Art 3D, which specializes in creating 3-D art tailored to CNC routing.

The company offers a library of stock, 3-D-relief designs that can be browsed, purchased and downloaded from their website. These can be carved as pieces to add onto a sign, or, if using software such as ArtCAM Pro, EnRoute Pro or Aspire, they can be used as elements within complex 3-D designs. Vector Art 3D also provides a catalog of 3-D art and custom modeling services.

Sometimes, subcontracting a project component to an expert like James soothes a signmaker. Because artwork developed from this painting would provide the sign’s focal point, I didn't want to take any chances.

AdvertisementI informed James about the project plans and sent him the TIFF file of the painting. In less than two weeks, he sent back a breathtakingly complex 3D model that we could readily incorporate into our project.

With James’ 3-D model complete, we finalized the sign’s vector-art design with Gerber's Omega® software, and then exported the design into Delcam's ArtCAM Pro software. We prefer ArtCam, when creating files for projects we fabricate using our ShopBot CNC router because it allows us to easily combine flat and 3-D cuts while providing all the necessary tools to process a sign’s diverse elements.

Creating dimension

After having created the 3-D toolpaths with ArtCam, we loaded a 3 x 4-ft. piece of 2-in.-thick, Sign*Foam® 3 HDU onto the ShopBot to start carving. Because of the relief model’s thickness, we initially roughed out the carving with a ¼-in., end-mill bit before we started using the 1/8-in., ball-nose bit to perform detailed carving.

The bas-relief carving alone required more than 36 hours in order to create the necessary detail. While the router fashioned the monk’s intricacies, we cut 6-in. x 6-ft., western red cedar boards to length and chopped them on the table saw before gluing them together to create the two sign panels needed for this project.

AdvertisementTo glue sign blanks together, we used West Systems’ epoxy – we’ve worked with this product for more than 15 years with flawless results. Because the sign’s length exceeds 20 ft., we created it as two separate panels to facilitate installation.

After having glued the boards, we placed the panels on the ShopBot and used a ½-in., end-mill bit to plane the sign blank’s surface. Next, we used a 110°, V-Carve router bit to carve the phrase "Fine Wines, Cheeses & Specialty Foods" into the main panels.

Paintin’ time

We primed and painted the signs with Glidden Endurance latex housepaint before we handlettered them with 1Shot® lettering enamel. Our shop’s philosophy is to not paint anything until it’s been completely carved. We recognize this contradicts the "paint before mask " school of thought that now dominates the industry. Over the long term, we’ve been very happy with this choice.

Painting, masking, carving through the mask and painting again creates its own headaches; paint peeling up with the mask during the final step provides the most common problem. We believe, although carving before painting requires considerably more time, it delivers a better and more consistent product and eliminates last-minute surprises and complications that can wreak havoc with deadlines.

Before painting the sign’s body, we masked the area where the bas-relief carving would sit, because we wanted the wood to bond to the Sign*Foam appliqué without any impeding paint. After painting, we peeled up the mask and laminated the monk carving onto the finished sign panel using West Systems’ epoxy.

Finally, we painted the sign’s carved portion. Again, we used latex house paint to create broad colors and achieved fine details with Cal-Western artists’ acrylics. Over the years, we’ve found these paints easy to use and very durable. The water-based acrylics provide a short drying window, but they deliver very controllable results. After having painted the carved element, I applied four coats of a clear, protective glaze.

This project was truly fun and challenging project to work on, and we were proud to assist the Bushes with their new business venture. We always encourage customers to "go the extra mile" and allow us to create something truly exceptional for them.

Equipment and Materials

Adhesive: West System epoxy, from West System Inc. (Bay City, MI), (866) 937-8797 or www.westsystem.com

Software: Gerber Omega, from Gerber Scientific Products. (Manchester, CT), (800) 222-7446 or www.gspinc.com; ArtCam Pro from Delcam (Windsor, ON, Canada), (877) 335-2261 or www.delcam.com

Digital Art: 3-D rendering, fromVector Art 3D (Burdett, NY), (416) 686 4591 or www.vectorart3d.com

Substrates: Western red cedar, available from specialty lumberyards; One-, 1½- and 2-in.-thick SignFoam 3 ® HDU, from Sign Arts Products (Laguna Hills, CA), (800) 338-4030 or www.signfoam.com

Paints: Glidden Endurance latex house paint, from ICI Paints (Cleveland), (800) 454-3336 or www.icipaints.com; Artists’ waterbased acrylic paints, from Cal-Western Paints Inc. (Santa Fe Springs, CA), (800) 559-5525 or www.cwpaints.com; and 1-Shot Lettering enamel from One Shot LLC (Gary, IN), (219) 949-1684 or www.1shot.com

Tools: ShopBot Alpha 48 x 96-in. CNC Router, from ShopBot Tools (Durham, NC), 888-680-4466 or www.shopbottools.com; router bits, from Gerber Scientific Products; drill, miter saw and table saw, available from home-improvement and building-supply stores.

More About J.D. and Lincoln Sign Co.

Lincoln Sign Co. (Lincoln, NH), a family-owned sign business that’s successfully served the Granite State’s White Mountain region from one location for more than 36 years, offers both flat and dimensional signs, as well as custom vehicle-graphics services.

J.D. Iles, who purchased the company in 2004, possesses an extensive signmaking background.

Prior to transitioning to Lincoln Sign Company, he worked for Hyatt's All Things Creative, a distributor of signmaking equipment and software. There, he trained equipment owners how to derive optimum value from their equipment and software. Before joining Hyatt's, J.D. worked for Stoner Graphics, a custom-commercial signshop in Harrisburg, PA, where he designed and fabricated custom, 3-D signs. J.D. also writes the Signs Never Sleep blog (www.signsneversleep.com), which showcases handsome custom signs from signmakers worldwide.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Orbus Celebrates Earth Day With Recycling Achievements

American Sign Museum Names New Executive Director

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery2 days ago

Photo Gallery2 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks6 days ago

Benchmarks6 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Ashley Borell