You just purchased a 1,000-sq.-ft./hr.-digital printer and are looking forward to producing yards and yards of profit-making images, but soon notice that you’re not generating the volume of prints you expected. You check the system to learn the printer is functioning properly and the supplied software seems to work okay, so what’s the problem? In this circumstance, our first look would be at the software, because the cure might be to install a more proficient software, i.e., a high-end, raster image processor (RIP).

So how does a proficient, high-end RIP help streamline operations? The image printing processes are straightforward: prepare the image, determine size and media type, and forward the job for printing, which is when the image codes move to the image processor software. Many operators don’t realize that the last step, the file-to-bitmap conversion, is the most intensive part of the process; it can delay other procedures from occurring until the image file forwards to the print queue, thus releasing the computer for other work. Our alternative is a high-end RIP, installed on a beefy and dedicated PC, which will noticeably accelerate these processes.

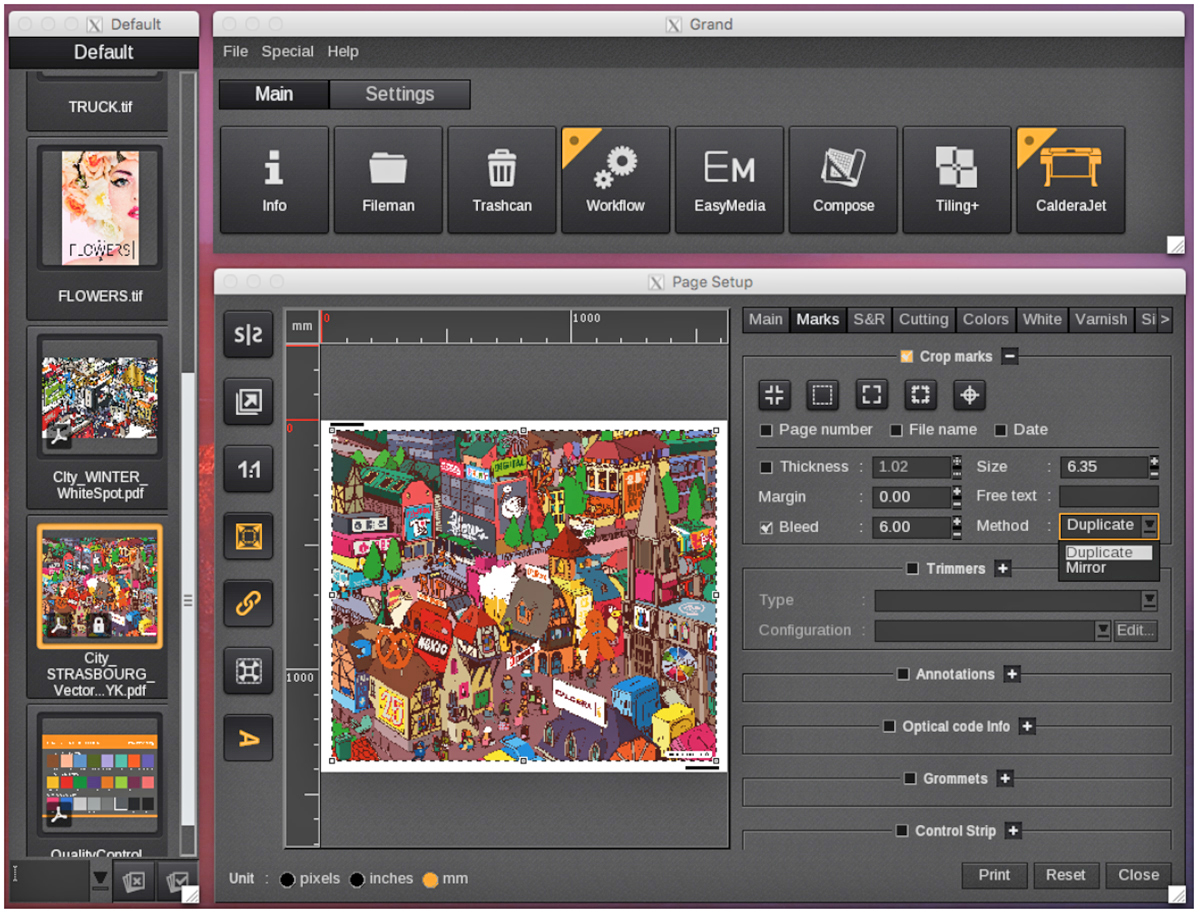

A premium RIP tied to a high-horsepower computer frees up the design stations to process the next job. And, with a premium RIP, the design workstation driver transfers the finished image files directly to the RIP processing queue. There, the RIP station takes over, processes the image files, queues them and directs them to the printer.

ADDING PRINTERS

Further, the more RAM, disk storage and processor core in the computer system, the better the speed and capacity. This type of design station, RIP software and print machine configuration can initiate a significant increase in print-process speed with one printer, but what happens if the printer itself becomes the bottleneck? In other words, what if your system is processing nicely, but the machine cannot print any faster?

The obvious solution is to add additional printers. For an upgrade fee, most major RIP companies will provide you with add-on systems that accept additional printers. Before deciding, be sure that both your computer hardware (and your market) can handle the additional load.

RIP EXTRAS

Though all high-end RIPs include ancillary systems, the most common are nesting systems that arrange a collection of images in a space-saving orientation to ensure efficient use of the media. You might also choose a RIP that offers sophisticated color correction tools, which allow saving work profiles that can be later employed on similar jobs. Your RIP choice may also include tools that create ICC color profiles, or tiling tools that will allow you to print large images (murals, wraps) in wide strips to be installed seamlessly or with overlap joints. Many printmakers enjoy a RIP accessory that on-command prints your placement choice of grommet holes and hem lines, which speeds your post-print finishing processes.

Advertisement

As you can see, a top-quality RIP can offer many advantages. If you’re just now purchasing a printer, talk with the manufacturer about RIP options or upgrades to their provided systems. Most digital printer manufacturers offer an initial RIP or image processor with an upgrade path for future expansion and this is what you want to explore. Also, note that your sign design software maker may offer an excellent RIP that fuses with their design software. Most importantly, recognize that a blue-ribbon RIP and a matched computer system may seem like an unnecessary expense, but in the long run such a system will save you money, time and media.

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery5 hours ago

Photo Gallery5 hours ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago