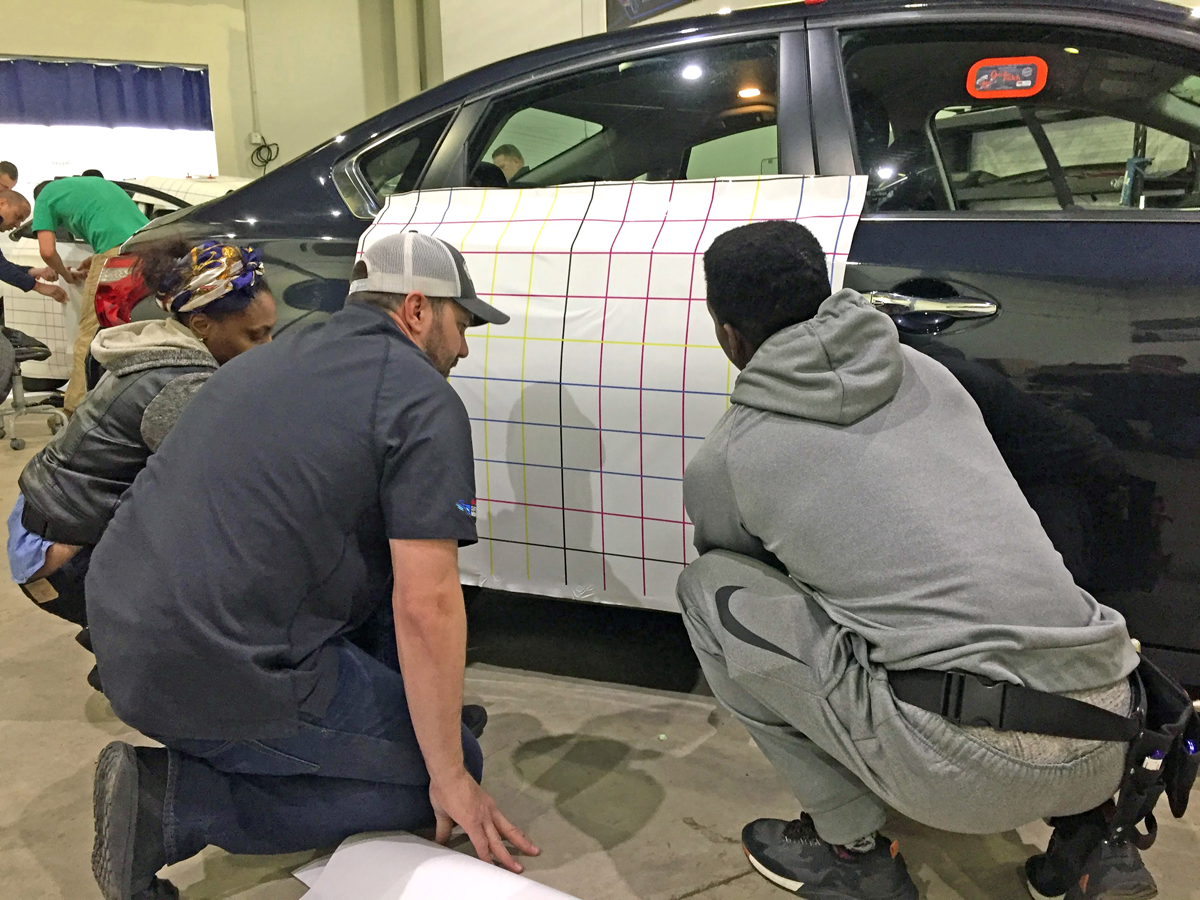

Last month, I had the privilege to sit in on a day of the Avery Dennison/Mutoh wrap class here in Cincinnati led by John Duever, president of Vinyl Images and Design (Fenton, MO). The two-day course covered the basics of floor, wall, window and vehicle wrapping. I took many pictures and some careful notes about what to do and what not to do when wrapping a vehicle. My thanks to the good people at Avery Dennison and also Vivid Wraps’ president Nick Durante for hosting us!

#1 DON’T OVERSTRETCH

I asked John Duever for the number one mistake vehicle wrappers make and he answered without hesitation, “Overstretching.” Specifically, stretching the vinyl too much when filling a gap such as a recessed portion of the hood, without post heating or even while heating. A more patient installer will pop up the portion of vinyl that’s bridging a gap and feed the vinyl into the recess while squeegeeing it down again. Overstretching damages the vinyl, will cause it to fail far before the warranty period, leaves wrinkles and is unsightly.

#2 POP AND LOCK

There is something of a dance to wrapping a vehicle, and if it helps, the second thing to remember is to “pop and lock” the vinyl. Once you’ve placed a film panel, it will naturally adhere to the vehicle’s body and have to be adjusted. A mistake that untrained installers commit, John said, is to pull the vinyl up slowly, thinking that the gradual manner of lifting it will best preserve its shape. Don’t do that. Instead, “Pop the vinyl up quickly with small, quick pulls,” John advised. A slower lift will actually stretch the vinyl more than popping it up. Pop the vinyl and squeegee as often as necessary before “locking it down” in its final position, then post heat the area if necessary.

#3 WORK IN TRIANGLES

Advertisement

Once you’ve locked down a portion of the wrap film, you’ll notice wrinkles fanning out from that point. John taught the class to recognize these “triangles” of wrinkled film and to work the squeegee in 45° angles to each side from the locked-down point. The angle of the squeegee on the film itself is also important. Try to hold it 30° to the vinyl. Triangles, 30°, 45° – what is this, geometry class? No, but you better do your homework.

#4 MIND THE WIND

Consider how the wind (and everything that’s blown into a vehicle by wind) will contact and affect the vinyl. Obviously, any little flap left will slowly but surely lift off the surface of the vehicle, and is to be avoided at all costs. So, when cutting and tucking vinyl into the spaces between body parts, such as the front edge of a door, cut the film so that you can tuck the remaining (hanging) vinyl well around the leading edge. If the vinyl is cut and left too close to the edge and not tucked around, the film is likely to loosen and fail over time. John calls this a “solid cut.”

#5 VINYL REMEMBERS

PVC-based vinyl – which comprises most wrap films – features an amazing recovery property when it’s heated. John demonstrated this by stretching some Avery Dennison MPI 1105 SuperCast Vinyl across an open car window, then pushing his fist a good six inches into it, leaving a huge concave impression. However, heating the area for just a few seconds caused the vinyl to shrink back and return to its original shape. The only way to prevent this (or to keep stretched vinyl in a new shape) is to post-heat to 180°F to change the properties of the PVC and give the vinyl new memory.

#6 KNIFE FIGHT

Advertisement

Cultivate a good relationship with your knife. Learn to feel the difference between simply cutting a strip of vinyl along a vehicle’s roof and cutting into the paint beneath. To avoid cutting into areas prone to damage, tape over them as you would when painting. Also, in most cases you want to use a 30° blade, though you’ll want a 45° blade when cutting window-perf vinyl on glass. Also, change the blade – often. “Almost with every new cut,” advised Kris Durante, install manager for our local host, Vivid Wraps, who also chipped in during the training. Immediately dispose of every used blade, John said, either by throwing it away or using a Blade Cage. “When your kid comes home from visiting your shop with a razor blade stuck in their shoe, you’ll never leave a blade on the ground again,” he warned.

In fact, John humorously related many learned-it-the-hard-way lessons. “Ask me how I know that,” he would say. I’m glad I did – and now you know, too.

Tip Sheet4 days ago

Tip Sheet4 days ago

Business Management2 weeks ago

Business Management2 weeks ago

Real Deal5 days ago

Real Deal5 days ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Benchmarks1 day ago

Benchmarks1 day ago

Editor's Note1 week ago

Editor's Note1 week ago

Women in Signs5 days ago

Women in Signs5 days ago

Line Time2 weeks ago

Line Time2 weeks ago