Digital Printing

Dye-Sublimination Primer

Dye sublimination may offer expanded business for your signshop.

Published

18 years agoon

What do dry ice and a graphics-printing process have in common? They’re both the end result of a naturally occurring phenomenon: sublimation.

The sublimation process converts a solid directly to a gas, bypassing the liquid state. Dry ice is a commonly known example. In the printing world, this phenomenon has been harnessed for dye sublimation.

Dye sublimation, which fuses ink to substrate, offers a durable option for creating personalized products, POP displays, corporate promotional items, decorative tiles, signage and other decorated products. For signage, dye sublimation has mostly been used for interior or short-term exterior signs. However, recent advances in substrates, dyes and coatings have begun to extend outdoor life far beyond previous capabilities.

How it works

Dye-sublimation "inks" comprise a liquid carrier mixed with fine dye granules. When heated to 400° F, typically in a heat press, the dye sublimates to a gas and is subsequently embedded in the substrate. In addition to activating the dye, heat and pressure open the pores of a polymer-based or coated substrate (sublimation won’t work on cotton or other untreated, natural substrates), which allows the dye in. When the substrate cools, its pores close; when the dye returns to a solid, it’s become a permanent part of the material.

Try to scratch a dye-sublimated surface, and the dye remains embedded — if the sublimation process is done correctly, it won’t chip off. You also won’t feel the image beneath your finger. This makes sublimated images durable without the need for lamination, in most cases.

AdvertisementDye-sublimation options include analog methods: traditional screenprinting and lithography; and digital-printing methods: inkjet, laser, electrostatic and thermal transfer. Another option, offset printing, is most frequently used for long print runs because setup is more expensive.

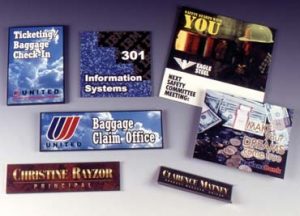

Offset, screenprinting and inkjet require sublimation inks, electrostatic and laser use toners, and thermal transfer necessitates ribbons. $image1

Inkjet printing

Printing with sublimation dyes isn’t new. However, using sublimation dyes in digital printers — to create transferable, color graphics — only gained popularity approximately a decade ago. It’s continued to grow as printers have improved.

"Printers have evolved," said Bob Keller, senior director of operations for Sawgrass (Mount Pleasant, SC). "In 1996, printers were nothing like they are now. Now, they have photorealistic output. They’re 20 times faster and have a microscopic dot size."

Specially formulated dye-sublimation ink is printed from an inkjet onto transfer paper. This paper is then placed on the substrate receiving the image (a ceramic tile, sign, a namebadge or coffee mug, for example). It’s then heated to create sublimation, as described above.

AdvertisementPiezo-electric inkjet, the most common printing process used for dye-sublimation transfers, works well because putting the ink on paper requires very little heat. You want the heat and sublimation to occur in the heat press when the printed transfer is placed on your substrate. Unlike thermal-inkjet printers, which use heat, the piezo-electric process pushes the ink onto paper using electrically charged crystals.

Making signage, or add-on products like namebadges or promotional materials, by printing dye-sub transfers and sublimating them to various substrates, appeals to most signmakers who want to expand their shop’s business.

In sublimation, an inkjet image is printed in reverse (on the transfer paper) and then transferred to a substrate. Because the dye hasn’t yet been heated, when an image is printed from a piezo-electric inkjet printer, the resulting image will look different — more dull — than it will after heat and pressure are applied, and the image is embedded into the substrate.

Your business’ dye-sublimation strategy will determine your piezo-electric-inkjet printer options. For small, dye-sublimated products, a desktop printer may be sufficient. For larger products, such as trade-show booth signage, a large-format print machine would be ideal.

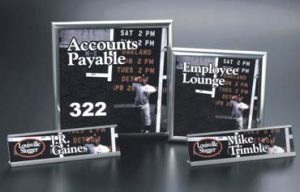

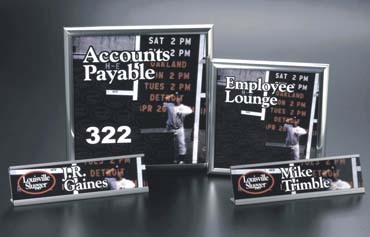

Many manufacturers’ solvent-based and waterbased inkjet printers can print sublimation dyes, though some makers may not support its use in their machines. A dedicated printer for dye sublimation is more cost and time efficient because switching back and forth from traditional to sublimation inks isn’t easy, said Clarence Matney, marketing manager for Unisub (Louisville). However, a few large-format printers use two inksets, so one machine could use both inkjet and dye-sublimation inks without having to clean and swap out the ink. $image2

In the signshop

AdvertisementKeller said inkjet is "it" for sublimated signs. "Electrostatic printing has mostly been replaced by inkjet for signage," he said.

Sublimation allows signshops to expand into ad specialties or use the technology to create signs, said David Gross, president of Condé Systems (Mobile, AL).

"Signshops are in an incredibly good position, because they already have the logos or artwork completed [for a customer’s signage order] and that’s the main work. With sublimation, they can make more money off the work they’ve already done."

For example, for a customer who needs tradeshow signage, a signshop can also sell namebadges, a carpet-tile mural for his booth and other dye-sublimation products. For a signshop, it’s complementary technology to its current business, Gross said.

"Customers want on-demand printing when they need it," Gross said. "Using sublimation allows you to print as you need it without excess or setup fees with a plate and printing press. Minimum order is one, so there’s no need for a setup fee."

Gross and Matney both estimated approximately $3,000 to get started in dye sublimation, assuming you need to buy a heat press, small-format printer, ink, transfer paper and substrates. Matney said $20,000 to $25,000 is a good estimate to get started with large-format, dye-sub printing. Most people designate one printer for dye sublimation when using inks. Dye-sub inks cost more than inkjet, so it’s cheaper to have a designated printer instead of wasting ink by switching/cleaning, he said.

Color management, a digital printing buzzword, also affects inkjet dye sublimation (you’re inkjet printing with dye-sub inks instead of traditional ones); color matching and color profiling remain concerns. The same design and image software, such as CorelDRAW® or Adobe Photoshop®, and RIPs used in most digital-print signshops, will work for dye sublimation. Dye-sublimation-specific software products are available, which include templates and profiles for such commonly sublimated items as T-shirts, dog tags or mugs.

Your ink manufacturer may have color profiles for your project. Just as with traditional digital printing, you’ll need a specific color profile for each combination of ink, printer and substrate.

Substrates

Additional sublimation-receptive materials are fueling dye sublimation’s expansion, Gross said. Polyester fabrics are commonly used for dye sublimation. Natural substrates won’t sublimate. But, some materials that can withstand the process’ high heat, without warping or melting, can be coated with sublimation-receptive polymers.

For example, Hanes Printables’ Soft L’ink T-shirts are cotton on the inside and polyester on the outside — perfect for sublimation. Frequently sublimated products include metal, hardboard, fiberglass-reinforced plastic (FRP), ceramic, wood, glass, leather and other materials.

Substrates should be white or light colored because you’re essentially dyeing the fabric (and black doesn’t dye), but that’s beginning to change, according to Gross. Condé will soon carry a hybrid-transfer sublimation paper that can transfer to dark shirts, he said.

"The number of available substrates is growing 20 to 30% per year," Gross said. That growth continues to expand the number of graphic-printed products created with sublimation.

Indoors or outdoors

Generally, dye-sublimated products are used indoors. Dye-sublimated signs could be used outdoors in the short term. Matney said most of Unisub’s products will last 18 to 24 months outdoors before any noticeable fading. Currently, sublimation isn’t meant for permanent, outdoor products. Recent innovations and product announcements should soon change that.

Dan Rutledge of Unique Imaging Concepts Inc. (Louisville), whose company dye sublimates on hard substrates to make POP, photo-reproduction and interior-architecture products, said he’s been experimenting with |2170| (Denver) Millennium XE coatings to extend outdoor life.Optima Intl.

Kolorfusion Inc.’s (Centennial, CO) patented process uses special coatings to make sublimated images UV resistant for five to 10 years (varying with the environment and sun exposure). The company’s president, Steve Nagel, said they select dye-sublimation inks based on UV-resistance. Additional coatings can further extend the image’s life, Nagel said.

The Kolorfusion process uses heat and a vacuum system, instead of a heat press, to create pressure. The company has licensed the process to major manufacturers of all-terrain vehicles, rifles, flashlights and faucets.

Thermal encapsulated color (TEC) film and tile, just introduced for Sawgrass and Tropical Graphics (Ft. Lauderdale, FL) sublimation inks, is geared to the signmaker. The dye-sublimation substrates reportedly offer three to five years of UV stability, sufficient for outdoor signage.

"I think you’ll see mainstream outdoor use [of sublimation] for signage in the next year or year and a half," Keller said.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet4 days ago

Tip Sheet4 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks23 hours ago

Benchmarks23 hours ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines